What is RFID Converting?

Simply stated RFID converting is taking the components of an RFID label - the printed material, the RFID inlay and the affixing adhesive - and manufacturing (or converting) the materials into a completed RFID tag. This is something becoming popular with traditional label converters.

Many converting companies now incorporate electronics in their finished products. Label converting produces RFID labels that incorporate RFID chips and antenna inlays. Volume electronics manufacturing practices including static electricity control, electronic manufacturing tests and similar processes are used by RFID converters.

Relatively new to the label industry, these practices have been incorporated into label converting using the experience of the past, modern technical know-how and a creative vision. These virtues solve the unique problems for label consumers, such as inclusion of materials sensitive to external influence into polymers. Roll-based manufacturing was an answer.

Roll Based RFID Converting

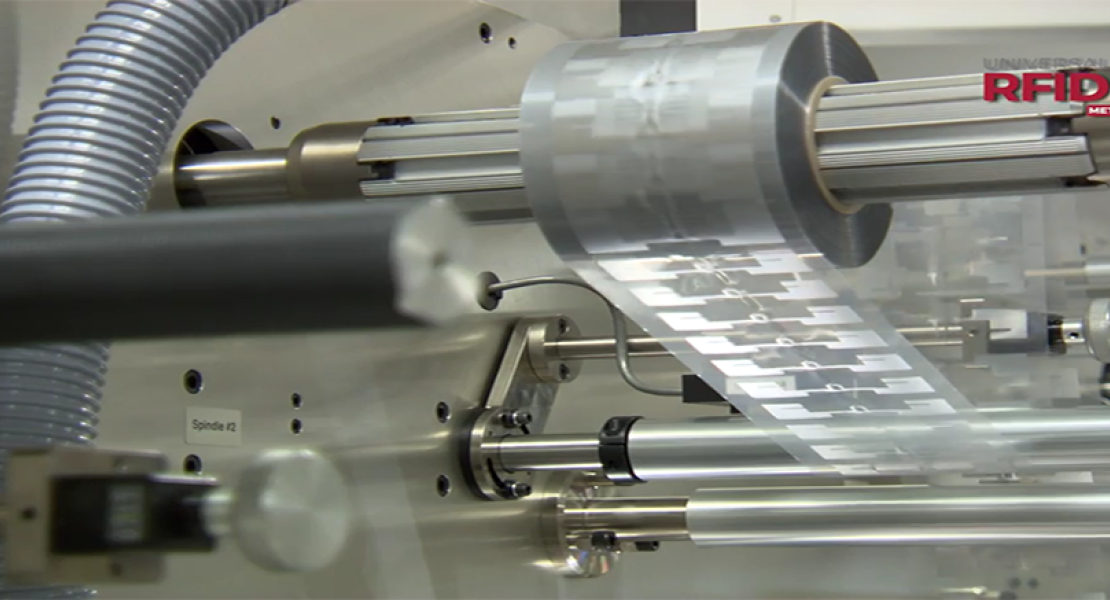

Well grounded in roll-based manufacturing, Metalcraft has a Viper roll-based converter. One of its features is precision cutting. This mechanical converter places wet or dry inlays at a high clip into substrates. Using lasers, the machine eliminates using a different die and anvil set for each inlay-wet or dry. It does different layered constructions in one pass saving time and additional labor costs.

The Viper also utilizes in-line verification across the UHF spectrum reading 2000 labels a minute with guaranteed performance. Even with the speed, the machine registers the product with precision alignment.

NFC Converting

Additionally, the RFID HF labels produced have high frequency programming capabilities. Even more specialized, the label can be manufactured with NFC (Near Field Communication) capabilities, hybrid RFID if you will, which is a popular choice for secure communication between consumer devices such as smartphones.

Within a close range of inches or less, NFC devices read passive NFC labels with low frequencies. If the label is compliant with ISO 15693 which offers a higher 13.56 MHz frequency and a read distance of 1–1.5 meters, it can contain commands for specific mobile applications such as opening and closing enclosures.

Metalcraft RFID Converting Capabilities

Other RFID and printing capabilities Metalcraft has to offer is the ability to record data in serial or list form and print in a human readable text on the label’s exterior. Additionally, Metalcraft provides a verified association file as documentation to ensure the tags have been programmed and printed correctly.

In praise of the Viper, Kyle Bermel, Metalcraft COO, says the viper “leads in a faster turnaround [for Metalcraft] and more product out the door”. This is a benefit also for you as you deal with the products you handle. In addition, such efficiency leads to lower production costs-again, a financial benefit to both the company and to you, the consumer.

Metalcraft RFID Label Converting Benefits

In general, RFID labels have wonderful properties; but they are an investment. Some companies may find that the return on their dollar does not warrant the purchase of RFID technology with all its bells and whistles. Thankfully, other technologies exist that are not as robust, but can be reasonable cost-saving alternatives like barcode labels, for instance, but RFID is definitely the path most business are taking into the future. http://www.veryfields.net/rfid-tag-development-trends-and-market-growth-opportunities

For those companies that can see RFID labels as a financial benefit, they offer many advantages. Without human assistance, real time readings on object data can be made without line of sight at multiple reading ranges and rates. Huge amounts of information can be stored on the chip so objects can be uniquely identified which, along with inventory concerns, discourages counterfeiting. RFID labels are able to trigger events: RFID windshield labels offer a more accurate and secure way to allow gate entry into various locations like secured communities, company/corporate secured parking or even car washes.

However, RFID label manufacturers are aware of the economic compromises companies must make and are dedicated to designing products for specific applications that are affordable and standardized.

Addressing this matter, Metalcraft's RFID tags and labels are superior to other RFID tags and labels because they are designed with durability and reusability in mind. Quality materials, innovation for the best product at the lowest cost and years of expertise enable repeated label usage. Enabled recycling drives down the cost per read, which in turn generates a greater return of investment.

| About the Author: Aaron HobertAaron Hobert is our RFID Technical Specialist. Hobert joined Metalcraft in September of 1994 as a Litho Press Operator, became the Autograph Team Lead in 1998 and in April 2005 he became the RFID Sales Support Rep. He was named our RFID Technical Specialist in 2008. Aaron lives outside Charles City with his wife Diane. Mobile Phone: 641-330-2660 Email: [email protected] Office: 3360 9th St. SW, Mason City, IA 50401 Office Phone: 641-423-9460 |