It comes as no surprise, we humans are fallible. We forget what’s in our closets. We misplace our cell phones. We’d lose our heads if they weren’t attached! This is where RFID tags can be useful.

Such fallibility is unfortunate in our personal lives, but it can be much worse for our companies.

But, then modern technology comes to the rescue.

Without mistakes, RFID, Radio Frequency Identification, uses radio waves to identify objects and track their movements. We don’t forget objects, and we know where they are. Using labels, readers and an IT system with software to receive, store and interpret data, an RFID network is used to emend our faults while expediting both business and pleasure.

What Are RFID Tags?

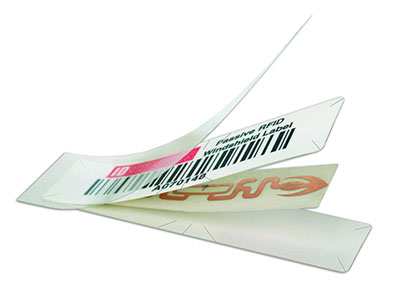

Of the three components of an RFID network, the label, which is attached to the object to be identified, is central. The labels usually are made of a substrate encasing a microchip/antenna inlay; together latter is called a tag. The labels are attached to objects as hanging labels or as flat labels applied directly to the object.

The microchip mounted on an integrated circuit is the heart of the label. This microchip contains encrypted information including the unique identification number and location of the object along with whatever other information the label buyer desires. Additionally, a programmer configures the microchip to contain the commands that control the operation of the chip itself including its operation as a passive or active tag and operational frequencies.

The chip and the circuit are mounted on a wafer of silicon. Usually a tiny antenna for transmission of information is robotically soldered to the circuit to complete the inlay, but, in some applications, the antenna is printed with metallic ink on a thin substrate and placed over the circuit to make a connection. Subsequently, the inlay, the functional portion of the RFID label, is supplied on a substrate as a dry inlay, or if adhesive is added, a wet inlay to a label manufacturer called a converter.

Around the inlay, converters form a sturdy RFID label.

Using a converter machine, the final form of the label takes shape. The inlay is encased in substrates made of different polymers for specific applications. Some RFID labels must withstand high temperatures, some must be resistant to abrasion, some must be water proof and so forth. Some must have color and holographics combining eye candy and functionality for pleasurable events like concerts. The label, too, might be embedded with a strong adhesive on the reverse of the tag to adhere to a customer’s assets.

Often, these adhesives have tamper-evident properties. For two tracking technologies, an additional plus on some labels is the ability to add customer programming that can be matched to printed barcode information.

After fabrication, the multiple labels on the sheet of composite substrates must be separated. As the composite passes through the press-like machine, its dies, lasers or razors are capable of cutting many different shapes to meet customer demand and object requirements.