A pallet label is the key to an efficient supply chain. The information contained within the label is the link between the physical asset and the information about that asset including potential information like where the pallet is from, where it is going, what the pallet contains, etc.

Why Is It Important to Label Pallets?

Pallets or other returnable containers are an important asset for companies to identify and track. Labeling pallets is one way to ensure these valuable assets are returned so they can be used again. Other reasons for companies to label pallets include:

- Identification - labeling pallets helps identify the contents of the pallets. By labeling a pallet, you can quickly determine what products are on the pallet, which can help with inventory management, order picking and shipping.

- Traceability - labeling pallets with unique identification numbers can help trace the movement of products throughout the supply chain.. This can be helpful in case of product recalls or if there is a need to track down a specific product for any reason.

- Compliance - many industries have regulations that require pallets to be labeled. For example, in the food and pharmaceutical industries, pallets need to be labeled with specific information such as lot numbers, expiration dates and production dates to ensure product safety and compliance with government regulations

- Efficiency - labeling pallets can improve warehouse efficiency by making it easier to locate and move pallets to the appropriate areas of the warehouse or distribution center.

What Should Be on a Pallet Label?

A pallet label should include the following information to help identify and track the contents of a pallet and/or the pallet itself:

- Product Information - this includes the product name, product code and a brief description of the product. This information can be helpful for inventory management and order fulfillment.

- Quantity - the number of items or products contained within the pallet should be clearly marked.

- Weight - the weight of the pallet including the products should be included on the label. This is important for shipping and transportation purposes.

- Pallet Dimensions - dimensions such as height, width and length of the pallet should be included on the pallet label.

- Handling Instructions - any special handling instructions or precautions should be included on the label. This includes information about whether the product is fragile, hazardous or requires special storage conditions.

- Date Information - if applicable, the label should include date information, such as the production date, expiration date, or best before date. This can help ensure that products are used before they expire.

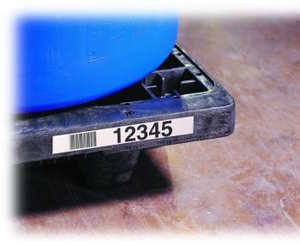

- Unique Identification Number - the pallet label should include a unique identification number that is easily visible on the label. This number should be specific to the pallet and not be used for any other pallet. The unique identification number can be represented using technologies like barcodes or RFID tags that can be scanned/read to track the product's movement throughout the supply chain.

- Shipping Information - the destination address and any other relevant shipping information should be included on the pallet label.

Including all this information on the pallet label, businesses can ensure their products are properly identified and tracked throughout the supply chain, which can help improve efficiency and reduce the risk of errors that may cause delay of payment or shipment.

What Technology Can You Use on a Pallet Label?

Technology such as barcode and/or radio frequency identification can help improve the efficiency and accuracy of the supply chain operations, making it easier to manage and track pallets through the supply chain, reduce errors and improve decision-making.

Using barcodes and/or RFID technology on pallet labels provides several benefits:

- Improved Accuracy and Efficiency - barcodes and RFID can help reduce errors and increase productivities by enabling faster and more accurate data collection. Scanning a barcode or reading an RFID tag is much faster and more reliable than manually entering data, and it eliminates the possibility of human error.

- Better Inventory Management - barcodes and RFID tags can help improve inventory management by enabling real-time tracking of pallets and products. This allows businesses to monitor inventory levels, identify shortages or excesses, and optimize inventory levels to meet demand.

- Increased Visibility and Traceability - by using barcodes and RFID tags, businesses can track pallets and products throughout the supply chain. This provides greater visibility and traceability, which can be important for compliance, quality control, and product recalls.

- Improved Supply Chain Efficiency - by using barcodes and RFID tags, businesses can streamline their supply chain operations, reduce costs, and improve overall efficiency. This can help improve customer satisfaction and drive business growth.

Why Do You Need a Durable Pallet Label?

Durability is important with pallet labels because pallets are subjected to a variety of harsh conditions throughout the supply chain. Pallets can be exposed to moisture, temperature changes, abrasion and other environmental factors that can damage or obscure the label.

A durable pallet label is more likely to remain legible throughout the supply chain, ensuring the information on the label can be read and processed. A damaged or obscured label can result in inaccurate or incomplete information about the contents of the pallet, leading to errors in processing, handling or incomplete information about the contents of the pallet, leading to errors in processing, handling, and shipping. In addition, certain regulations or industry standards that pallets labels remain legible and intact throughout the supply chain. Lastly, a durable pallet label can reduce the need for re-labeling, thereby saving time and money in the supply chain.

Overall, a good pallet labels should provide all the necessary information to identify and track the pallet and its contents, and it should be designed to be clear, readable and durable. For information on durable pallet labels or to receive FREE samples, contact us at 800-437-5283 or [email protected].

| About the Author: Marianne AlvaradoMarianne Alvarado is our Vice President of Sales. Alvarado joined Metalcraft in March of 2000 as a Territory Specialist, became Sales Manager in January 2022 and was named Vice President of Sales during August of 2023. She leads both the Outside and Inside Sales teams. Marianne lives in Davenport with her husband, Dave Beeman. Mobile Phone: 641-529-9492 Email: [email protected] Office: 3360 9th St. SW, Mason City, IA 50401 Office Phone: 641-423-9460 |