Rusty's Weigh Scales, Metalcraft Partner To Provide Complete Solution to Customers

Creating efficiencies is a primary benefit of implementing systems using radio frequency identification (RFID) technology in any industry for a wide variety of applications – even some that may surprise you.

Background

Headquartered in Lubbock, Texas, Rusty’s Weigh Scales started manufacturing custom weigh scales in 1982 for a variety of industries, weighing items a light as a gram to weighing freight trains. In 2003, founder and owner, SD “Rusty” Jones decided to “scale” back and focus on large industrial scales – including those found in the cotton gin industry.

Objective

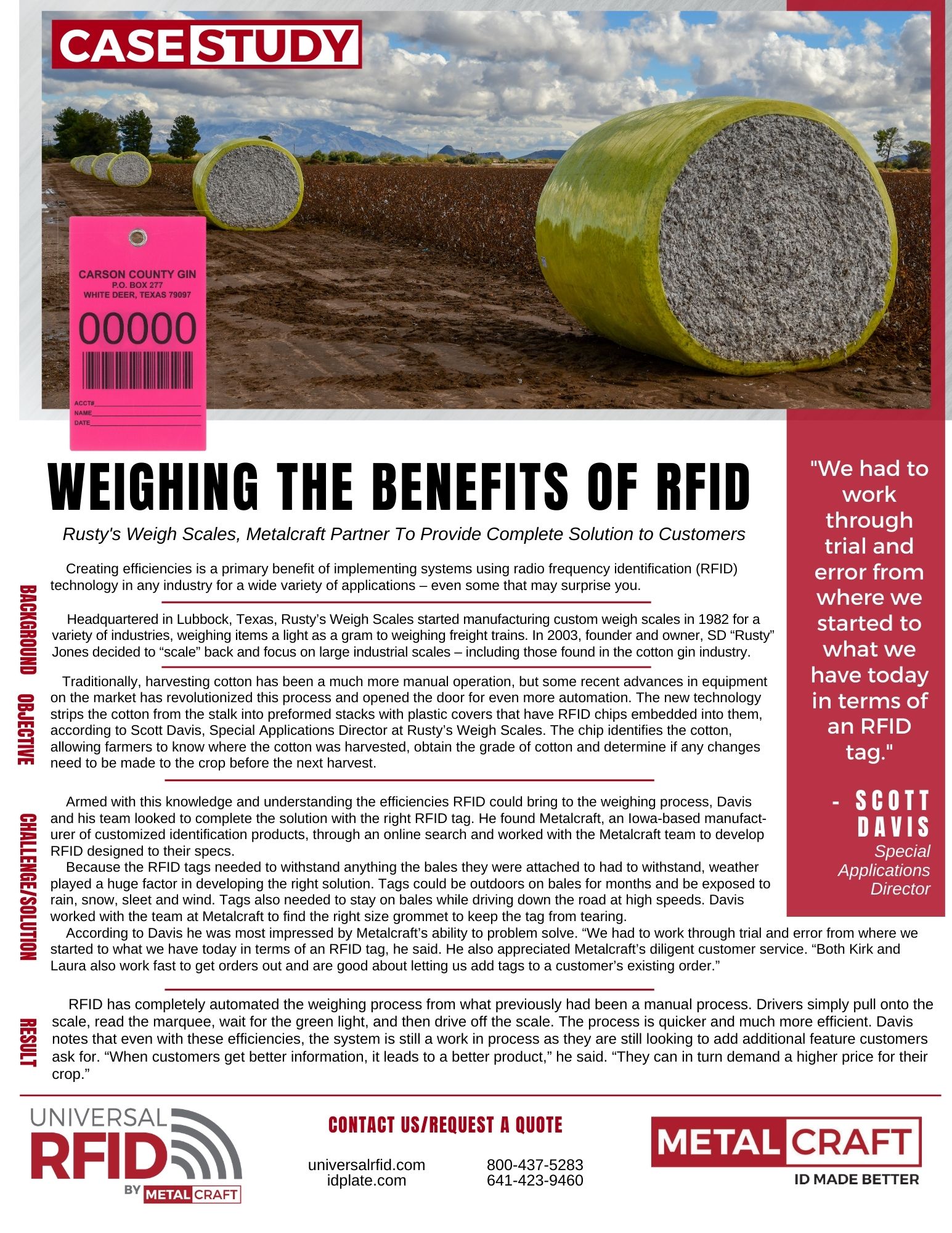

Traditionally, harvesting cotton has been a much more manual operation, but some recent advances in equipment on the market has revolutionized this process and opened the door for even more automation. The new technology strips the cotton from the stalk into preformed stacks with plastic covers that have RFID chips embedded into them, according to Scott Davis, Special Applications Director at Rusty’s Weigh Scales. The chip identifies the cotton, allowing farmers to know where the cotton was harvested, obtain the grade of cotton and determine if any changes need to be made to the crop before the next harvest.

Challenge/Solution

Armed with this knowledge and understanding the efficiencies RFID could bring to the weighing process, Davis and his team looked to complete the solution with the right RFID tag. He found Metalcraft, an Iowa-based manufacturer of customized identification products, through an online search and worked with the Metalcraft team to develop durable RFID designed to their specs.

Because the RFID tags needed to withstand anything the bales they were attached to had to withstand, weather played a huge factor in developing the right solution. Tags could be outdoors on bales for months and be exposed to rain, snow, sleet and wind. Tags also needed to stay on bales while driving down the road at high speeds. Davis worked with the team at Metalcraft to find the right size grommet to keep the tag from tearing.

According to Davis he was most impressed by Metalcraft’s ability to problem solve. “We had to work through trial and error from where we started to what we have today in terms of an RFID tag, he said. He also appreciated Metalcraft’s diligent customer service. “Both Kirk and Laura also work fast to get orders out and are good about letting us add tags to a customer’s existing order.”

Result

RFID has completely automated the weighing process from what previously had been a manual process. Drivers simply pull onto the scale, read the marquee, wait for the green light, and then drive off the scale. The process is quicker and much more efficient. Davis notes that even with these efficiencies, the system is still a work in process as they are still looking to add additional feature customers ask for. “When customers get better information, it leads to a better product,” he said. “They can in turn demand a higher price for their crop.”

To learn more about our asset tracking solutions, contact us today at [email protected].