Using a Label Converter For Your Application

A converter commissioned to create a label will listen to your ideas about the label you’re ordering by asking you questions.

Primarily, what is the purpose of your label?

In reality, the successful outcome of your label rests upon your answer to this one question. All others reference it to clarify your vision of your label for the label converter. Then, other questions follow.

Will your label only be used to inventory items?

If so, the label converter just needs to design the label with a barcode in mind. But what kind of barcode? Simple? Human readable characters and alphanumerics? Complex? 2D barcodes including DataMatrix and QR Codes? And, what size?

The label has to be sized to accommodate text and graphics or, to the contrary, text and graphics have to be configured to the label.

Will the label converter also need to account for your company’s security in the label? If so, tamper-evident adhesives or polymers that crumble would be in the order. And perhaps serialized codes?

And finally, perhaps, will the label converter need to build a label that identifies and promotes your brand?

If so, your company name and logo will likely be on the label. Then, again, label size? Will your logo suffer in resizing? Will you want it colored? If so, does it, specifically, need to be “your” color using the Pantone matching system (PMS), a standard language for color identification and communication or could you use a stock color? Do you want eye-catching glitz? Then, perhaps, glitter or holographics?

These decisions must be taken into account by the label converter.

Label Converting & Data Management

Yet, beyond these decisions ( which many customers might consider routine data entry specifications) label converters like Metalcraft that do converting actually must set the wheels in motion to convert all the specifications into a digital script the converting equipment will read to turn out a product. Here is where the label converter’s experience as a materials engineer really comes into play. Label converters must mesh the tangible with the intangible to accomplish the job. They do this by creating computer scripts (programs) that cover two types of information the labeling equipment must follow.

The first, customer based, is the digitized information the customer has related and wants the label to carry, and second, company based, is the digital pattern the converting equipment is given to go about creating the label itself. To do the latter, label converters must understand the nature of all sorts of materials: polyester, anodized aluminum, stainless steel, polycarbonate, ceramic and more. Additionally, they must understand how to manufacture a label to withstand environments ranging from mild to extreme and resist abrasion, caustics/acids, solvents, salt air, high temperatures, and UV rays.

Considerations need to be taken into account about compatible substrates, adhesive compatibility, material durability and a host of other concerns.

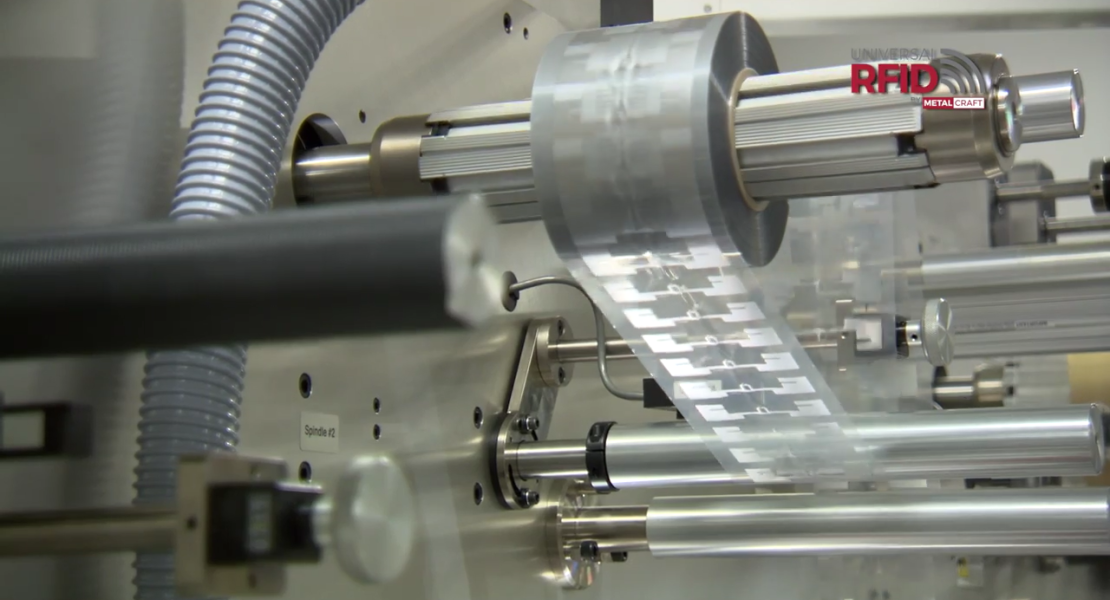

Understanding these needs and capabilities, label converters script complex workflow patterns noting material needs. When correctly fed to the equipment by a label converter, the converting equipment responds to the script following strict directives like the nip points at which layers of polymers attach to their fellows or like registry sets that allow smooth flow of materials for precise material alignment.

Label converters are specifically trained to do this and often receive industry certification for their expertise.

Converter Expertise

Working hand in hand with the label converter in the office, a technician on the floor uses computers networked to the script to put into motion and monitor the the equipment as label creation takes place. This trained technician handles the setup of materials, monitors the inline computers that continually give job data in progress, resolves abnormalities and makes other observations to maintain production efficiency. His operational know-how is a valuable component of label converter production.

If you are in doubt about the skills employed by label converters and the production value of the converter itself, perhaps in your experience, you have tried to affix an adhesive backed plastic liner (Contact paper, for example to a shelf). Remember how taut and parallel you had to hold the sticky, unrolled plastic sheet as you attempted to place it on the shelf’s surface?

You had the best luck in covering the shelf, if you had a friend to help you smooth and flattened the plastic sheet as you progressively laid it down from one end of the shelf to the other. The friend squeezed out bubbles and pulled out wrinkles as they occurred. You took care not to stretch the plastic sheet as you tried to align it to the shelf while keeping it from awkwardly sticking to you or to the shelf prematurely. A neatly covered shelf was an achievement!

Now, relate that task to the label converter’s task of programming and calibrating a machine to stack layers of sticky stuff together to make a product. The modern achievement it is that layers of thin web can be printed with your logo and information, adhered, with no bubbles or wrinkles, to other, multiple layers, precisely aligned and neatly and sharply cut to create a product. Label converters make it happen.

Metalcraft uses the DeltaEdge Laser converting machine managed by gifted label converters to produce outstanding labels. No luck, no magic, just exceptional people working to give you what you pay for.

To learn more about our asset tracking solutions, contact us today at [email protected].

About the Author: Marianne Alvarado

Marianne Alvarado is our Vice President of Sales. Alvarado joined Metalcraft in March of 2000 as a Territory Specialist, became Sales Manager in January 2022 and was named Vice President of Sales during August of 2023. She leads both the Outside and Inside Sales teams. Marianne lives in Davenport with her husband, Dave Beeman.

Mobile Phone: 641-529-9492

Email: [email protected]

Office: 3360 9th St. SW, Mason City, IA 50401

Office Phone: 641-423-9460