What is Contract Converting?

Contract converting refers to a business model where a company specializes in providing comprehensive services related to the conversion of raw materials or semi-finished goods into finished products. This process typically involves various manufacturing, assembly, or packaging services.

Contract converting plays a pivotal role in streamlining production processes for their clients, offering expertise and resources to handle specific manufacturing stages. This outsourcing model allows companies to focus on their core competencies while leveraging the specialized skills and capabilities of the contract converter. The contract converting industry spans various sectors, including packaging, printing, and manufacturing, providing tailored solutions to meet the diverse needs of businesses seeking efficient and cost-effective production processes.

What is RFID Contract Converting?

RFID contract converting involves hiring a third-party vendor to handle the design and manufacturing process for an RFID implementation. Organizations work with specialized RFID converters who are experts in RFID solutions, including designing and manufacturing RFID inlays.

By outsourcing RFID converting tasks to a third-party provider, businesses can leverage the vendor's knowledge and resources to expedite project timelines, ensure successful implementation, and optimize the benefits of RFID technology while focusing on their core operations.

Why do Companies use Other Companies for Contract Converting?

Companies may opt for contract converting for several strategic reasons:

- Expertise and Specialization - contract converting companies often possess specialized knowledge, skills, and equipment related to specific manufacturing processes. By outsourcing to such specialists, a company can benefit from their expertise without needing to invest extensively in developing the same capabilities in-house.

- Cost Efficiency - contract converting can be a cost-effective solution for businesses. Outsourcing eliminates the need for substantial capital investment in machinery, facilities, and personnel, as the contract converter bears these costs. This can result in significant cost savings for the contracting company.

- Focus on Core Competencies - contract converting allows companies to concentrate on their core competencies and strategic activities. By delegating certain manufacturing processes to specialized partners, businesses can streamline their operations and allocate resources more effectively to areas where they have a competitive advantage.

- Flexibility and Scalability - contract converting provides flexibility in production capacity. Companies can adjust production volumes based on demand fluctuations without the challenges associated with managing excess capacity during downtimes. This scalability is particularly advantageous in industries with variable demand patterns.

- Speed to Market - contract converting can expedite the time it takes to bring a product to market. Specialized manufacturers may have established processes, resources, and supply chain networks that enable faster production and delivery, allowing companies to respond quickly to market demands.

- Risk Mitigation - out sourcing certain manufacturing processes to contract converters can help mitigate risks associated with technology changes, market uncertainties, or regulatory compliance. Contract manufacturers often bear responsibility for staying current with industry standards and regulatory requirements.

- Reduced Overhead and Administrative Burden - by outsourcing manufacturing processes, companies can reduce the administrative burden associated with managing complex production operations. This includes tasks such as hiring and training personnel, maintaining equipment, and overseeing day-to-day manufacturing activities.

- Quality Assurance - reputable contract converting companies often adhere to stringent quality control standards. This can result in improved product quality and consistency, as these manufacturers are experienced in meeting industry regulations and standards.

In summary, companies opt for contract converting to leverage external expertise, achieve cost savings, focus on core functions, enhance flexibility, mitigate risks, and gain access to specialized capabilities and resources. The decision to use another company for contract converting is often driven by a strategic assessment of how outsourcing can contribute to overall operational efficiency and business objectives.

Why Inlay Innovation/Metalcraft for Contract Converting?

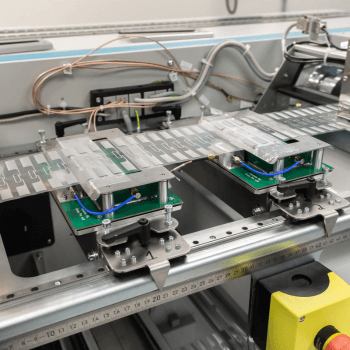

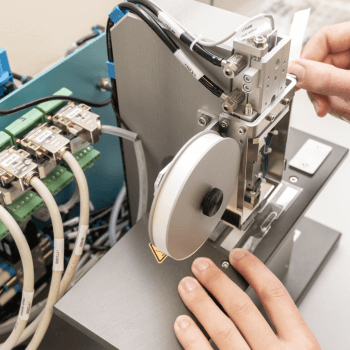

Inlay Innovation, a subsidiary of Metalcraft, Inc., is a custom RFID inlay design and manufacturer. Beyond custom designs, we are committed to being your full-service RFID partner. Our identification experts will help you every step of the way from initial design of your inlay through the manufacturing process. Here's just a few of the reasons Inlay Innovation should be your partner in RFID.

- Quality Driven - Both Inlay Innovation and Metalcraft are ISO certified showing our customers we are committed and comply with the highest manufacturing standards in the industry to ensure our product performs as expected every single time.

- Industry Recognized - We are a Global RAIN RFID inlay manufacturer.

- Scalable Production - No job is too big or too small. We have the production capacity to meet the demand you need.

- Extensive Customization - Regardless if you already have an inlay design or need us to develop a custom inlay design to meet your needs we've got you covered.

- Made in the USA - We offer US-based designs and manufacturing with a sustainable supply chain that will not disrupt you or your customers.

The only thing “mini” about this tag is its size! With a smaller footprint and lower profile, the Onsite Printable Universal Mini RFID Tag easily fits where other tags may be too large and obtrusive and still gives incredible read ranges compared to other tags in its class.

Want more? More performance, more savings, and more sustainability? Then you want Metalcraft’s new Universal Eco-Mini RFID Tag!

Want more? More performance, more savings, and more sustainability? Then you want Metalcraft’s new Universal Eco-Mini Plus RFID Tag!

From The Asset Tracking Blog

Beyond RFID Tags: Top Questions About RFID Technology

We answer your top questions about RFID technology, including its definition, inventory management and cost.

Demystifying the RFID Inlay Manufacturing Process: From Concept to Card

Want to know how an RFID inlay is created? This article breaks down the process from designing to the finished product.

RFID Dry Inlays vs. Wet Inlays: Choosing the Right Tag for Your Application

RFID inlays come in various types, and this article breaks down how wet and dry inlays are designed for different applications.