What are photo anodized tags?

Photo anodized tags are durable and long-lasting identification tags that are created using a specialized photo anodizing process. This process involves transposing photographs or other images onto the surface of anodized aluminum tags, resulting in permanent and highly durable markings. Here's an overview of the key features and benefits of photo anodized tags:

- Material: Photo anodized tags are typically made of aluminum, which undergoes an anodizing process to create a protective layer on the surface. This anodized layer provides durability, corrosion resistance, and a smooth surface for printing images.

- Photo Anodizing Process: In the photo anodizing process, a photosensitive layer is applied to the surface of the aluminum tag. A photo negative containing the desired image or text is then placed in contact with the photosensitive layer and exposed to light. This exposure transfers the image onto the surface of the tag, creating a permanent bond between the image and the metal.

- Durability: Photo anodized tags are highly durable and resistant to wear, fading, and corrosion. The anodized layer on the aluminum surface provides additional protection against environmental factors, ensuring that the markings remain legible and intact even in harsh conditions.

- Customization: Photo anodized tags can be customized with various types of images, including logos, text, barcodes, serial numbers, and photographs. This allows for highly detailed and personalized markings to meet specific identification requirements.

- Applications: Photo anodized tags are widely used for asset identification, labeling, and signage in various industries, including manufacturing, aerospace, automotive, healthcare, and utilities. They can be used indoors or outdoors, in extreme temperatures, and in environments where exposure to chemicals or abrasion is a concern.

- Versatility: Photo anodized tags are available in various shapes, sizes, and mounting options to suit different applications. They can be attached to equipment, machinery, products, or infrastructure using adhesive backing, rivets, screws, or other fastening methods.

Overall, photo anodized tags offer a combination of durability, customization, and versatility, making them a preferred choice for high-quality identification and labeling solutions across diverse industries and applications.

What is the Photo Anodized 5 Point Promise?

Anodized metal, once primarily associated with machine tools and architectural applications in the latter half of the twentieth century, has found a versatile new use: transposing photographs onto its surface. This innovative technique, utilized for over five decades, stands as a cornerstone method for exporting labels and barcodes onto metal surfaces. Unlike laser engraving, often misconstrued as a more permanent technique, photo anodizing preserves the metal's outer layer intact. Instead, the process involves printing photo negatives onto polyester film, which are then exposed onto photosensitive metal. The resulting labels boast exceptional longevity and durability, surpassing other mainstream treatment methods.

Moreover, imprints onto metal via photo anodizing can undergo an intensification process. Here, a second coating is applied, sealing the developed image beneath successive anodized layers, further enhancing its resilience.

At Metalcraft, we harness the power of photo anodizing in our asset ID tagging, labeling, and barcoding processes. So confident are we in the benefits of photo anodizing that we've established a succinct set of principles, our "five-point promise," ensuring the efficacy of our photo anodizing services and our commitment to durability and efficiency:

- Superior Durability: We guarantee that our nameplates and foil labels will withstand even the harshest conditions, enduring weather and general wear-and-tear with ease.

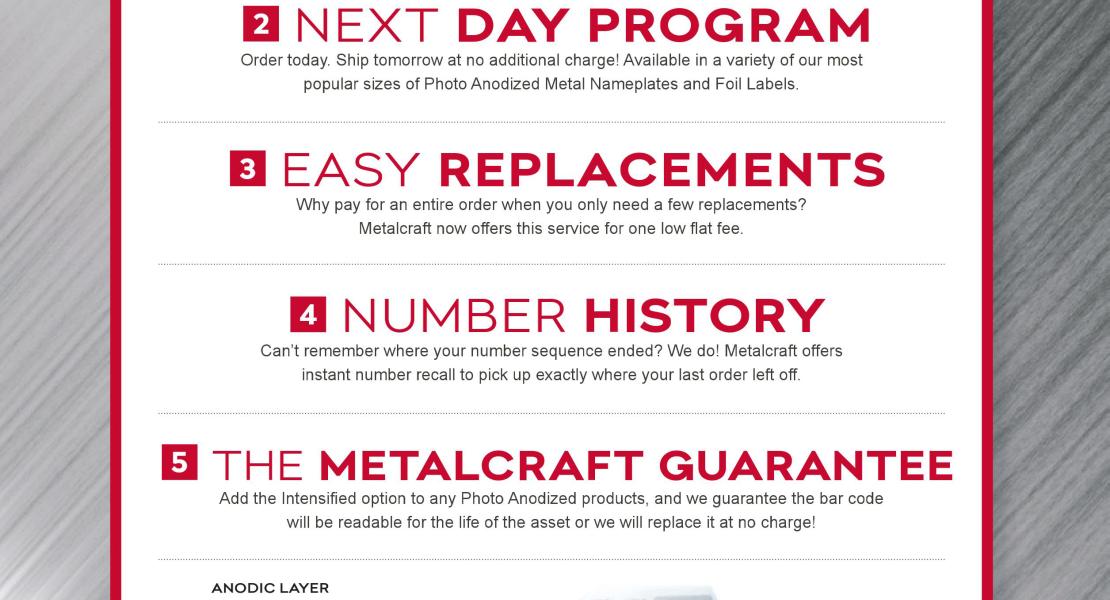

- Next Day Program: For seven of our most popular sizes of photo anodized plates, orders are dispatched the following day at no additional cost, ensuring swift service.

- Easy Replacements: Replacement nameplates and foil labels can be obtained for a flat fee, ensuring hassle-free maintenance.

- Number History: Our instant number recall feature allows you to seamlessly continue numbering from your last order, eliminating the need to remember previous numbering sequences.

- The Metalcraft Guarantee: Opting for the intensified version of our photo anodized products ensures a lifetime guarantee of barcode functionality for the asset's lifetime, exemplifying our commitment to quality and longevity.

Few companies would stake their reputation and future business on such promises, especially offering a lifetime guarantee. However, craftsmanship and honesty are paramount values at Metalcraft. Our word is as dependable as our proficiency in anodizing.

Why are photo anodized tags superior?

Photo anodized plates offer superior durability and longevity compared to other labeling and marking techniques for several reasons:

- Preservation of Metal Integrity: Unlike laser engraving, which removes material from the metal surface, photo anodizing preserves the integrity of the metal's outer layer. This ensures that the label remains intact and durable, even under harsh conditions.

- Photosensitive Process: Photo anodizing utilizes a photosensitive metal surface, onto which photo negatives are exposed. This process creates a permanent bond between the image and the metal, ensuring that the label withstands wear and tear over time.

- Additional Protective Layers: Photo anodized plates can undergo an intensification process where additional anodized layers are added on top of the developed image. These layers provide extra protection, making the label even more durable and resistant to environmental factors.

- Resistance to Wear and Corrosion: The anodized layers formed during the photo anodizing process provide excellent resistance to wear, corrosion, and fading. This ensures that the label remains legible and functional for an extended period, even in challenging environments.

- Versatility in Applications: Photo anodized plates are suitable for a wide range of applications, including asset ID tagging, labeling, and barcoding. They can be used indoors or outdoors, in industrial environments, or in harsh weather conditions, making them versatile and adaptable to various settings.

Overall, the combination of a photosensitive process, additional protective layers, and resistance to wear and corrosion makes photo anodized plates a superior choice for durable and long-lasting labeling solutions.

To discover more about our aluminum tags and learn how our photo anodizing services can benefit your business, contact us today at [email protected].

About the Author: Marianne Alvarado

Marianne Alvarado is our Vice President of Sales. Alvarado joined Metalcraft in March of 2000 as a Territory Specialist, became Sales Manager in January 2022 and was named Vice President of Sales during August of 2023. She leads both the Outside and Inside Sales teams. Marianne lives in Davenport with her husband, Dave Beeman.

Mobile Phone: 641-529-9492

Email: [email protected]

Office: 3360 9th St. SW, Mason City, IA 50401

Office Phone: 641-423-9460