Tags That Last: The Benefits of Photo Anodized Metal Nameplates and Labels

From traffic signs and computers to mission-critical medical and industrial equipment, photo anodized tags are the go-to solution when your labels just have to work.

Table of Contents

Don’t have time to read the entire guide right now?

Fill out the form for a downloadable PDF version of the guide you can reference later

Chapter 1

Metal tags are some of the best asset management solutions on the market today. Compared to polymer-based asset tags and other label materials, metal asset tags offer enhanced durability and reliability for more demanding applications.

And many applications are more demanding than youmay think. Between sunlight exposure, user wear and tear, extreme temperatures, and harsh environments/chemicals, many tags are subjected to challenging conditions that cause them to fade, become unreadable or completely fall off the asset.

For all of these problems, metal asset tags are the solution. The following features prove the enhanced durability and reliability of metal asset tags.

UV Resistance - Sunlight and UV rays can cause a typical tag to rapidly fade and deteriorate. Metal asset tags do not fade as quickly when exposed to sunlight, making them a better solution for any equipment that is going to frequently be out in the sun.

Abrasion Resistance - If you plan on moving your assets around frequently, or they're on an asset in harsh conditions, then they will likely face wear from abrasion. Forklifts, pallet jacks and even rough operator handling can scrape and wear down your asset tags, which can affect their performance and reliability. Metal tags offer high abrasion resistance, making them the best choice for crates, containers and anything else that will get a lot of traffic.

Extreme Temperature Endurance - Polyester and polypropylene tags start to discolor and deteriorate at temperatures higher than 300°F. Metal asset tags, on the other hand, typically have no issue with breakdown or discoloration with temperatures up to 750°F. If your assets have to go through any kind of tempering or heated process, metal tags are your best bet. This also applies to extreme cold.

Chemical Resistance - If your asset is frequently exposed to cleaning or caustic chemicals. It can break down and ruin non-metal asset tags. Glass cleaners, bathroom cleaners, alcohol, acetone and other common chemicals can erode plastic tags, making them unreadable. Metal ltags are not as affected by these chemicals, keeping the tag in good condition while allowing your asset to stay clean and meet inspection requirements.

Chapter 2

While standard metal tags are a great choice for durable and long-lasting asset management, photo anodized metal tags are even better. Photo anodized tags improve upon the inherent strengths of standard metal tags, making them even more resistant to whatever you throw at them.

Unlike surface printed products, photo anodized tags offer enhanced durability even in the most extreme environments. Photo anodized tags, nameplates, and labels are made using a photo imaging process that seals the tag's image or barcode under a sapphire-hard anodic layer. This glass-clear anodic layer offer extra resistance to harsh chemicals, paint, abrasion and dirt while the tag's aluminum base will not peel, crack or deteriorate. The black graphics or the seal image itself are made of metallic silver particles that will hold up to harsh environmental conditions.

Intensification - For even more protection, photo anodized tags can also go through an optional intensification process that extends the outdoor life of the tag. This intensification process improves the heat durability and UV resistance of the tag, allowing them to last 20 plus years in the grueling outdoors.

Teflon® Metal Nameplates - For highly corrosive or abrasive applications, Teflon can be a great option. Teflon-coated metal tags offer all the advantages of intensified photo anodized tags, while also allowing you to easily clean off dirt, grease, grime and even dried paint from the surface of the tag.

High-Temperature Tags - Specialty high-temperature tags are available for when you are facing the most extreme temperatures. High-temperature tags are ideal for applications with temperature requirements beyond 900°F, with a maximum of 1200°F, making them a most cost-effective alternative to other expensive high-temp materials such as ceramics and stainless steel.

Webinar Events

MODEX 2024 brings those who are a part of the supply chain together to discuss manufacturing and supply chain solutions.

A Quote can go here -

or an important statement statistic or surprising fact.

Checklist or Bullets

- Bullet poines and lists are agreat way to

- Break up longer copy and display

- Complex information in an easyto read format

Case Studies

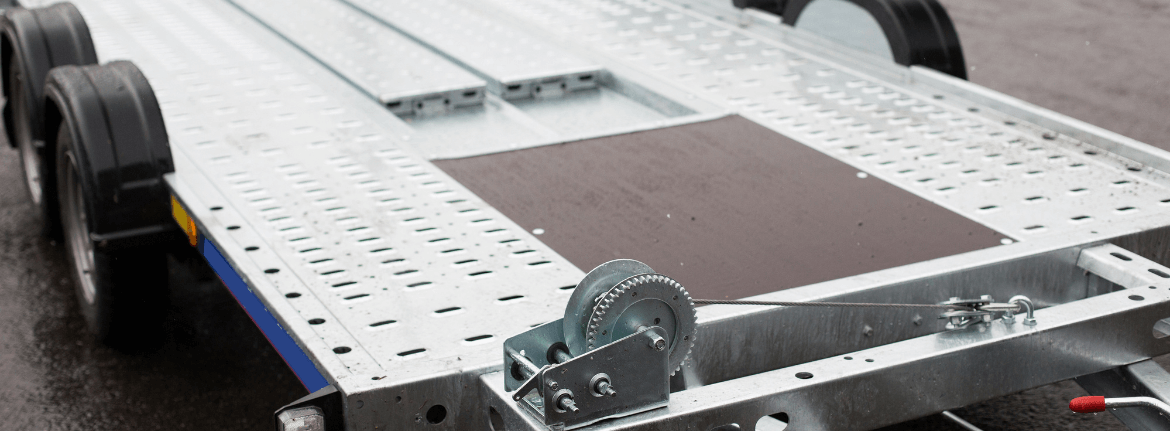

Durable Tags Never "Trail" the Competition

Background

In the competitive landscape of the trailer manufacturing industry, effective product identification is crucial for brand recognition, customer satisfaction…

Creating a Memorable "Experience"

Background

Experiential marketing has seen a remarkable growth in recent years, transforming the landscape of traditional brand promotion. This dynamic approach…

Tracking "Spirited" Barrels

Background

Minden Mills Distilling is part of Foley Family Wines, a Sonoma Valley-based portfolio of highly acclaimed wines since 1996 and represents the expansion of…

Chapter 3

Withthe enhanced durability of photo anodized tags, along with the different options available, these metal tags can fit with any application that you can think of. Common industries to find photo anodized tags in are:

Construction - From tool control to original equipment identification, photo anodized barcode labels are great for tool tracking and management. Abrasion, chemical exposure, and high temperatures are all commonplace on a construction site, making the enhanced durability of photo anodized tags a necessity. Foil tags can also conform to curved surfaces, making them a great option for managing a variety of handheld tools.

Medical and Military Equipment - both the medical industry and the military sector face harsh conditions and equally challenging regulations. From chemical washdowns in healthcare to constant abrasion and wear in the military, common asset tags are pushed beyond their limits. With photo anodized metal tags, these conditions are non-issues. These tags are also UID compliant, making them an ideal solution for the DoD mandate.

IT, Retail and Office Equipment - Electronics, vending machines, fitness equipment - all of these things needs tags. If you are reading this on your office computer, it probably has a tag on it. Metal asset tags help to make sure that these can always be easily identified and tracked.

Shipping and Storage - Whether your asset is sitting in a storage facility or actively in transit, it has to be properly tagged so that you can keep track of it. Large shipping containers, pallets, and individual packages can use all photo anodized tags so that you inventory management is not compromised by harsh handling conditions.

Infrastructure and Roadway Management - From stop signs and power poles to fire hydrants and traffic lights, things that we see outside our windows on our commutes are usually identified with photo anodized metal tags so that governing agencies can keep track of assets in outdoor conditions without having to constantly re-apply tags.

Other uses for photo anodized metal tags include:

- Picnic tables and playground equipment

- Wine barrels

- Amusement park rides

- Transformers

- Engines

- Audio/visual equipment

- Casino slots and equipment

Resource

Asset management applications in manufacturing - includes real-world case studies for both barcode and RFID.

What is the best solution for asset tracking in manufacturing? Read our latest article to learn how to determine what identification products in your asset tracking solution in manufacturing.

Chapter 4

Here at Metalcraft, we take a full-service approach to better asset tagging. Our industry-leading tagging solutions include standard photo anodized metal tags, intensified options, high-temperature tags and Teflon coated metals.

In addition to providing better metal tags and labels, our tagging experts work with you to guarantee that your tag can meet all of you needs. That way, you will never have to look for another tag ever again.

Resource

Discover why the design of the inlay is so important to RFID tag construction and how it can greatly affect the performance for your application in this white paper.

December 11th is Charles Walton's birthday, an inventor who played a huge role in bringing RFID technology into the mainstream. We're declaring this day as National RFID Day.

Chapter 5

To truly capitalize on the benefits of photo anodized tags, we partner with you to make sure that you specify the right one for your asset and application. Getting this right on the first try will help save you from the future headache of having to get new tags and redo the application process on your assets.

That is why Metalcraft places such a big emphasis on getting the right tag for the right application. Not only do we want to avoid the tag falling off or failing in the field, but we also want to make sure you are not overpaying for extra functionality or durability that you do not need.

With Metalcraft's DART Qualification Process, our proven project discovery phase ensures that every detail is accounted for in your labeling project. The DART process is defined by the following steps:

- Defining the Project Objective - the first step of any successful project is to define what the goals are. By defining the project objective, we can set realistic expectations for the project, as well as determine which tagging technology is best for the application.

- Asking Questions - no application is the same. If you want to make sure that all the unique requirements of your application are accounted for, you need to ask the right questions. Metalcraft's tagging experts will ask questions surrounding the asset's surface, potential chemical exposure, environmental conditions and operational temperatures to help narrow down potential product options.

- Recommending a Product - once we have defined the project objective and asked all the right questions, our specialists will determine the best product for your specific application. We make sure that you get exactly what you need - nothing more, nothing less. For instance, if your tag isn't going to be put outside or face temperatures above 500°F, then there is no reason to go through the extra intensification process when a standard photo anodized tag will offer durability and reliability just right for your project. Metalcraft will never recommend a the higher cost of intensification if your application does not need it.

- Testing Samples - no good qualification is complete without testing a product in the actual environment that you will use it in. After determining the right asset management technology, Metalcraft sends out free test samples to your facility to ensure that everything works in the field as it does in the lab.

Serialize/unserialized ... barcode and human readable ... we help you sort out your RFID numbering options to choose the best one for your application.

Chapter 6

The most expensive and often overlooked component of any asset tracking system is the labor cost of applying the tags. Once

you get your tags, the quicker that you can correctly apply them to your assets, the more efficient and cost-effective your inventory

management will be.

This is not just a matter of having your operators work faster – older tags simply could not be applied in an efficient manner. Technology was the issue, as older tag liners were difficult to remove and often led to users contaminating the exposed adhesive.

That is why the experts at Metalcraft have streamlined the tag application process with our tabbed metal tags. The breakaway tab

assists in nameplate application, promoting proper liner removal while reducing application time by over 30 percent. By more

easily allowing users to handle the nameplate while only touching the edges, they can avoid contaminating the exposed adhesive,

ensuring maximum adhesive performance and tag life.

For even quicker tag application, Metalcraft has also designed the QuickTab Tag Dispenser. This revolutionary, patented ring makes

applying tags fast and easy, allowing your operators to tag your assets almost 3 times faster than doing everything by hand.

The QuickTab Tag Dispenser also eliminates the risk of adhesive contamination, ensuring that your tags stay on your assets after

they are applied. Other benefits include:

- Easy liner removal

- Consistent numerical sequencing

- Minimized potential of losing nameplates

- Convenient scrap collection

- Easy portability

What Our Clients Say

Chapter 7

Ready to see what photo anodized metal asset tags can do for your operation? Talk to Metalcraft today for an expert look into your application and which type of tag is right for you. Think you have a project that our tags can’t handle? We are ready to prove you wrong. Contact us to see if you are the very first application that is too tough for a Metalcraft tag.

Metalcraft does more than just supply quality tags – we enable better asset management. Not only can we guarantee that you get the

right type of tag through our DART Qualification Process, but we also offer custom options for every aspect of your label needs. Barcode

symbologies, attachment adhesives, shape, size, color, and copy font are all customizable, along with QR code options.

Once you get the perfect tag, Metalcraft takes care of your data management at no additional charge. We keep a detailed history

of your serial numbers and an electronic report of your tag’s custom programming to ensure your asset management always

stays on track.

That’s ID Made Better.

Dont Miss Expert Updates from Metalcraft

Subscribe to our blog updates for the latest in industry advancements