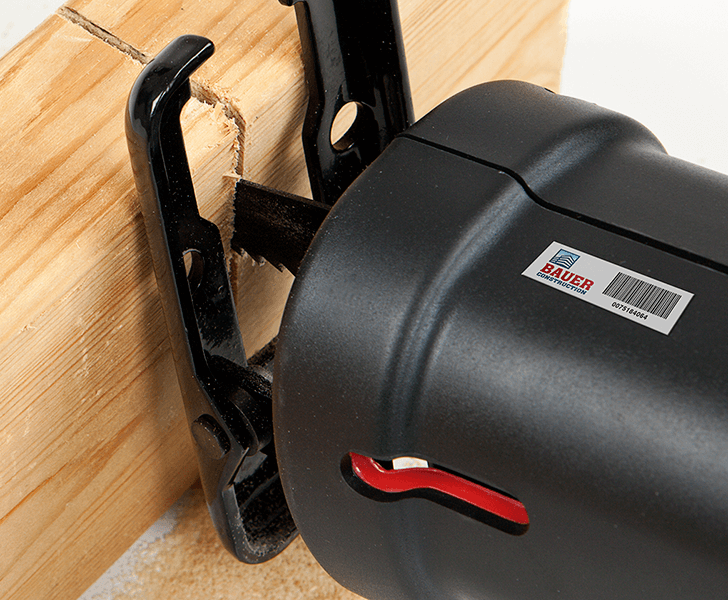

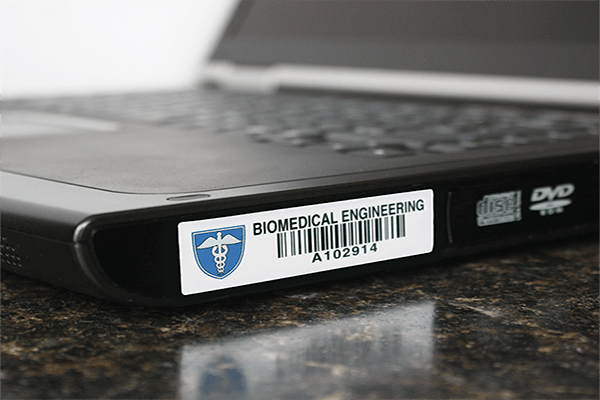

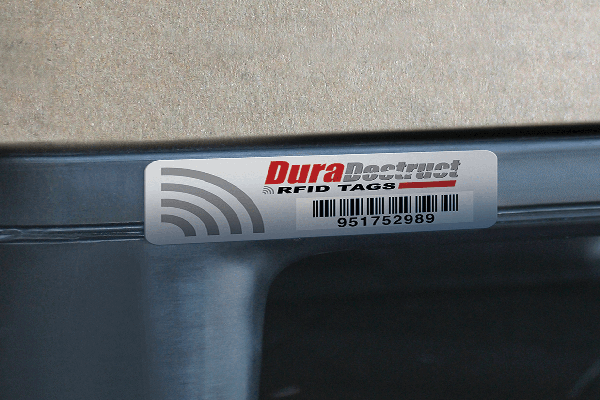

Misplaced assets are a challenge for any business, so tracking and keeping order around supplies helps you save valuable time and money—you’re not wasting time tracking down assets or wasting money replacing equipment you can’t find. Asset tracking labels—whether RFID, barcode or other tracking technology—are designed so the asset can be easily identified and tracked in any environment. Not only is the construction customizable (paper, plastic, metal, etc.), you can also customize your asset tags with text, logos, sequential numbers, barcodes, RFID and more.

The closest thing you will find to a one-size-fits-all RFID solution!

The closest thing you will find to a one-size-fits-all” RFID solution!

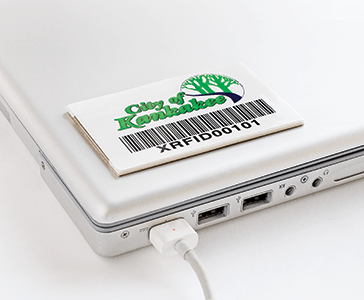

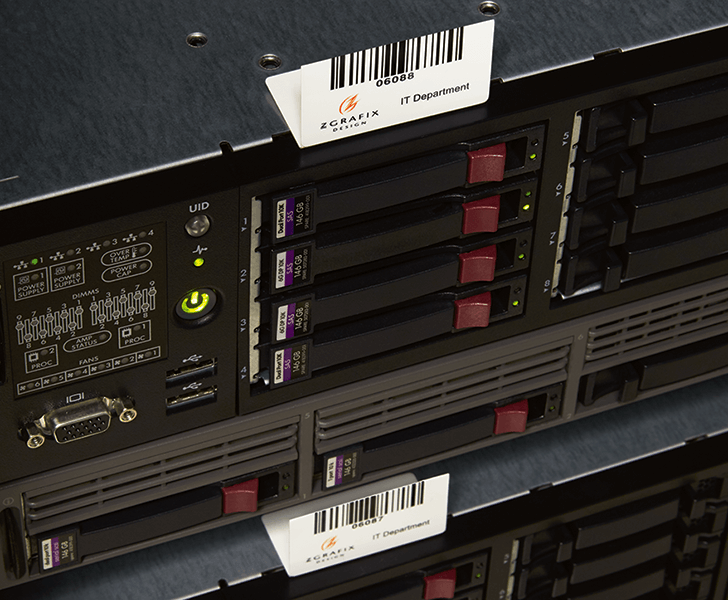

A great alternative to metal mount applications where a standoff will not work, Metalcraft’s RFID Server Rack Tag consists of an adhesive label that protects the encapsulated RFID inlay and a non-adhesive, folding tab that offsets the RFID inlay.

A versatile and affordable RFID tag made in the USA to fit a wide array of on-metal and standard applications, the Universal MC RFID Tag is available both preprinted and onsite printable to handle whatever asset tagging application you have.

Metalcraft’s RFID Flex Hard Tags are specifically designed for assets that need a rugged, yet flexible, polymer RFID tag that is more cost effective than traditional hard tags and has a reliable, consistent read range performance.

The perfect solution for tracking assets on metal or non-metal surfaces that do not allow for attachment directly to the asset. The construction protects the inlay from environmental conditions that could affect the performance of the RFID tag.

Perfect for tracking returnable containers such as pallets, crates or totes, Metalcraft’s Standard RFID Tag attaches directly to non-metal assets.

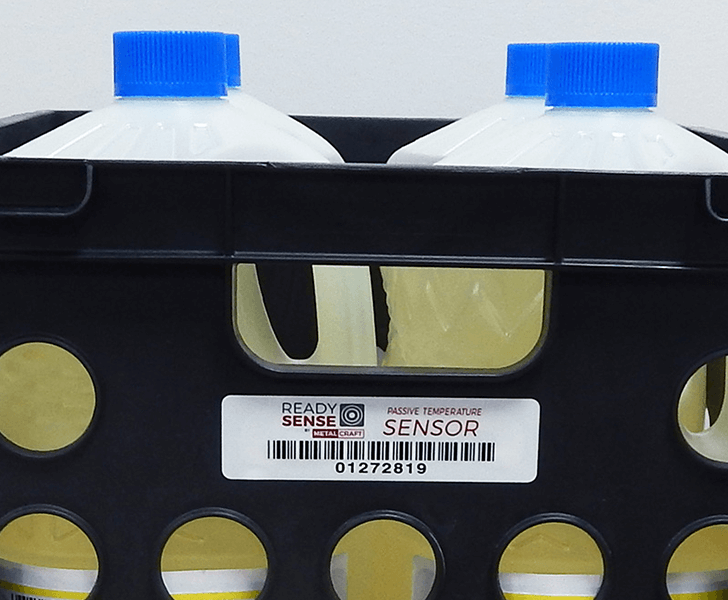

The ReadySense Passive RFID Temperature Sensor Tags are much smaller, thinner, and more flexible than battery-powered sensors, and they are more cost-efficient than active wireless sensing tags.

Perfect for applications that need a bit more than just adhesive, Metalcraft’s Stick and Staple RFID Tag attaches directly to assets with adhesive with the added option of stapling the tag, ensuring the tag stays attached to those hard-to-adhere surfaces while not damaging the inlay.

An RFID tag that truly lives up to its name. The Universal RFID Hard Tag features surface-independent tags with a patented inlay design used to obtain excellent read ranges regardless of the surface – metal, plastic, even wood.

The only thing “mini” about this tag is its size! With a smaller footprint and lower profile, the Onsite Printable Universal Mini RFID Tag easily fits where other tags may be too large and obtrusive and still gives incredible read ranges compared to other tags in its class.

The Universal Micro RFID Tag measuring 1 7/8” x 5/8” is a great solution to your identification projects that require the smallest RFID tag with great read range.

If you are looking for a small RFID tag, the Universal Mini RFID Tag is the one for you! The Universal Mini RFID Tag may be small in size, but it packs a powerful punch! Its compact design and slim profile make it ideal for spaces where larger tags would be cumbersome.

The closest thing you will find to a "one-size-fits-all” RFID solution!

What is Asset Tracking?

Asset tracking is the process of monitoring and managing physical assets, equipment, or inventory within an organization. It involves using technology, such as barcodes, radio frequency identification (RFID), or other tracking systems. The primary goal of asset tracking is to improve efficiency, reduce losses, enhance security, and streamline overall operations.

Key aspects of asset tracking include:

- Identification - assigning unique identifiers such as barcodes, QR codes, or RFID tags to each asset for easy tracking.

Tracking and data management – using technology to monitor the location and status of an asset. Collecting and managing data related to asset information, maintenance history, and other relevant data.

Automation – implementing automated systems that can update asset information without manual intervention, reducing the risk of human error.

- Reporting and Analysis – generating reports and analytics based on the collected data to make informed decisions, optimize asset utilization, and identify areas for improvement.

Where is Asset Tracking used?

Asset tracking is widely used in various industries, including manufacturing, logistics, healthcare, retail and more. It helps organizations save time, reduce costs, and improve overall operational efficiency by providing visibility into their asset inventory.

What are the benefits of Asset Tracking?

Asset tracking offers several benefits to organizations across various industries. Some of the key advantages include:

- Improved Visibility - asset tracking provides visibility into the location and status of assets, enabling organizations to know where their valuable resources are.

- Reduced Losses and Theft – by monitoring assets closely, organizations can quickly identify and respond to instances of theft or unauthorized uses.

- Optimized Asset Utilization – efficient tracking allows organizations to optimize the use of assets, ensuring that they are deployed where and when they are needed. This can lead to better resource utilization and cost savings.

- Enhanced Productivity – with accurate information on asset location and status, organizations can streamline workflows, reduce downtime, and improve overall productivity

- Preventative Maintenance – asset tracking systems often include maintenance tracking features. This enables organizations to schedule and perform preventative maintenance based on usage patterns, reducing the risk of unexpected breakdowns and extending the lifespan of assets.

- Cost Saving – by preventing losses, optimizing asset usage, and implementing preventative maintenance, organizations can achieve significant cost savings over time.

- Compliance and Accountability – asset tracking helps in maintaining compliance with regulations and industry standards. It also promotes accountability by keeping a record of asset movements and usage.

In summary, asset tracking contributes to operational efficiency, cost savings, security, and overall organizational effectiveness by providing accurate information about the location, status and usage of assets.

Why is Asset Tracking important?

Asset tracking is important for several reasons, and its significance extends across various industries. Here are some key reasons why asset tracking is considered crucial.

- Cost Savings - asset tracking helps organizations optimize the use of their assets. This can result in cost savings over time.

- Loss Prevention – by monitoring the location and status of assets, organizations can quickly identify and respond to instances of loss, theft or misuse.

- Improved Productivity – knowing the location of assets streamlines operations. It reduces the time spent searching for equipment, tools, or inventory, leading to increased productivity and streamlined workflows.

- Enhanced Security – asset tracking systems contribute to improved security by providing a means to monitory and control access to valuable assets.

- Customer Satisfaction – for businesses involved in delivering products or services, accurate and timely asset tracking contributes to meeting customer expectations.

- Data-Driven Decision Making – asset tracking systems generate valuable data that can be analyzed to make informed decisions about procurement maintenance strategies, and overall operational improvements

Asset tracking is important because it helps organizations save costs, prevent losses, improve security, enhance productivity, and make informed decisions based on accurate information about their assets.

From The Asset Tracking Blog

Metalcraft Could Revolutionize Retail Industry Inventory Tracking

Our new Universal Eco-Mini and Eco-Mini Plus RFID Tags are perfect for retail tracking on metal surfaces.

Why is Asset Tracking Important for Businesses?

Corporate asset tracking helps business operations, enhances efficiencies, reduces costs, improves customer satisfaction and ensures regulatory compliance.

What are the Components of an Asset Tracking System?

Read our latest article to learn more about the components of an asset tracking system including asset tags or labels, barcode scanners or RFID readers and asset management software.

Asset Tracking - RFID Case Studies

On the Road with BallerTV

BallerTV uses Metalcraft RFID tags to track their incoming and outgoing inventory of livestreaming equipment.

Handmade Social Media

Studio Fiveighteen teams with Metalcraft to reimagine "social media".

Automotive Supply Chain Moves Better with RFID Packaging

Universal RFID tags track $27 million packaging in closed loops