RFID can make any WIP more agile and efficient, and with an almost endless list of potential applications, it’s a relief to have the RFID deep knowledge and expertise in your partner, Metalcraft. Working together, just like RFID and WIP, we can elevate your solution to one with benefits you may not have even thought of, custom-designed just for you….Now that’s ID Made Better®.

A versatile and affordable RFID tag made in the USA to fit a wide array of on-metal and standard applications, the Universal MC RFID Tag is available both preprinted and onsite printable to handle whatever asset tagging application you have.

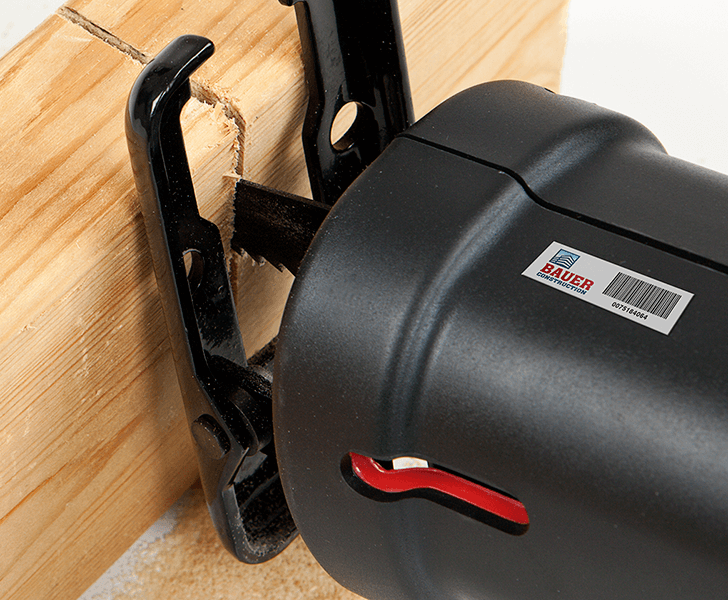

The perfect solution for tracking assets on metal or non-metal surfaces that do not allow for attachment directly to the asset. The construction protects the inlay from environmental conditions that could affect the performance of the RFID tag.

Perfect for tracking returnable containers such as pallets, crates or totes, Metalcraft’s Standard RFID Tag attaches directly to non-metal assets.

The only thing “mini” about this tag is its size! With a smaller footprint and lower profile, the Onsite Printable Universal Mini RFID Tag easily fits where other tags may be too large and obtrusive and still gives incredible read ranges compared to other tags in its class.

The Universal Micro RFID Tag measuring 1 7/8” x 5/8” is a great solution to your identification projects that require the smallest RFID tag with great read range.

If you are looking for a small RFID tag, the Universal Mini RFID Tag is the one for you! The Universal Mini RFID Tag may be small in size, but it packs a powerful punch! Its compact design and slim profile make it ideal for spaces where larger tags would be cumbersome.

The closest thing you will find to a "one-size-fits-all” RFID solution!

What is RFID WIP Tracking?

RFID (radio frequency identification) in work in process (WIP) tracking refers to the use of RFID technology to monitor and manage the various stages of production or manufacturing process. RFID is a technology that use radio waves to identify and track objects wirelessly. In the context of work in process tracking, RFID is utilized to provide real-time visibility into the status and location of items as they move through different stages of production.

Here's how RFID WIP tracking generally works:

- Tagging Items – each work in process item, such as components or products, is equipped with an RFID tag. This tag contains a unique identifier that can be read by RFID readers.

- Readers and Antennas – RFID readers with attached antennas are strategically placed at different points along the production line. These readers emit radio waves to communicate with RFID tags.

- Data Transmission – as work in process items move through the production process, the RFID tags transmit data to the RFID readers. This data typically includes information such as the item’s identity, manufacturing stage, and timestamps.

- Centralized System – the collected RFID data is sent to a centralized system or software platform. This system processes the information and provides real-time insights into the location and status of each item in the production cycle.

What are the Benefits of RFID WIP Tracking?

RFID enables real-time tracking of items, allowing manufacturers to monitor the progress of production and identify bottlenecks or delays. In addition, RFID eliminates the need for manual data entry, reducing errors and improving overall efficiency in tracking work in process. Automation is another benefit of RFID WIP tracking. The automation of tracking processes with RFID technology streamlines production workflows, leading to faster and more responsive manufacturing. Lastly, RFID tracking provides a detailed history of each item’s journey through the production process, facilitating traceability for quality control and compliance purposes.

From The Asset Tracking Blog

Custom Hang Tag Offers Flexibility and Versatility for a Variety of Applications

Metalcraft's customized RFID hang tag can be hung from the asset or attached with mechanical fasteners, providing a flexible and durable asset tracking solution.

Metalcraft's RFID Tag Tops In Industry Reports Study

University of Texas at Arlington study confirms that an RFID tag from Metalcraft will perform reliably and accurately with better than average readability.

What is RFID? A Basic Guide to Radio Frequency Identification

Integrated chip ... antenna ... substrate .... these are all parts of what makes up and RFID tag. Our guide explains these components as well as takes a look at the different types of RFID tags.

Work-in-Process - RFID Case Studies

Production Floor Efficiency

Valley Chrome Improves Work In Process Using Universal Micro RFID Tag

Valley Chrome Plating in Clovis, California is a leading manufacturer of chrome plated aftermarket diesel truck parts like bumpers, cab panels, visors and other various decorative chrome items that go on semi-trucks.

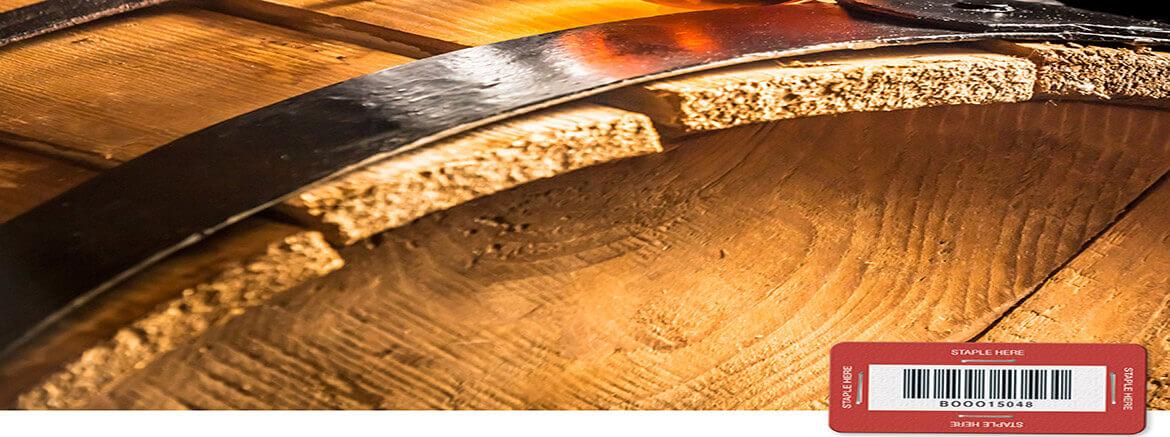

Tracking Spirits

GlobeRanger and Metalcraft team up to provide ID solution to whiskey distillery

Opportunity

Making whiskey is an age-old process that large distilleries have down to a science. One large US-based distillery wanted to improve their data collection process by integrating RFID technology to track and utilize data about a critical asset in the production process – the barrel.

Global Leader Uses RFID To Improve Manufacturing Process

A global leader with increasing demand for their products entrusted Metalcraft and CDO Technologies to collaborate on a solution to increase traceability and accuracy. The goal was to improve efficiency and profitability through automating work-in-process operations, using Radio Frequency Identification (RFID).