Even beyond data redundancy, a barcode can still be a powerful tool in the pursuit of better asset management. While they lack many of the more industrious and attractive qualities of RFID, their tried-and-true nature still has benefits for many applications, sometimes even in place of RFID.

What is barcoding? How does a barcode work?

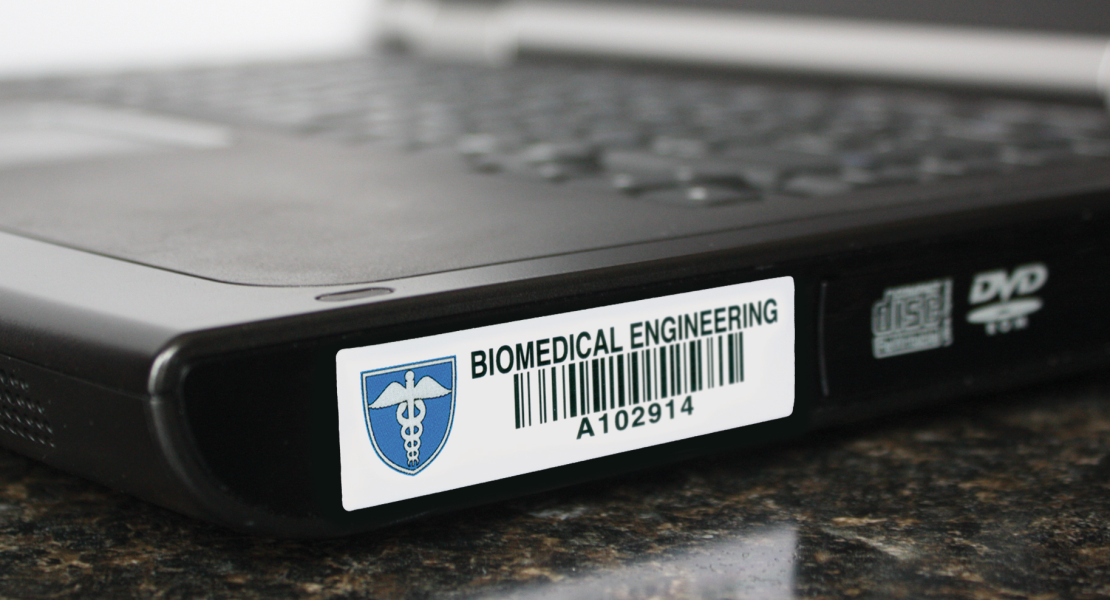

Barcodes are a series of black and white stripes that are used to represent information. These stripes comprise alternating thick and thin likes that form a series of "bars" on the affixed label. Each letter or number can represent different products, and the code is unique to each product. Barcodes can be scanned by a reader which then uploads the information into a computer.

What kinds of barcodes are there?

There are two types of barcodes: linear (or one-dimensional) and two-dimensional. Linear barcodes are the most common type and are found on most products. A linear barcode is made up of series of thin black bars and spaces that are arranged in a particular pattern. When scanned, this pattern is turned into digital information that can be read by computers.

symbologies.

Two-dimensional barcodes, also known as stacked codes, are more complex than linear barcodes, provide more information, hold more data and are easier to read when printed on small objects. Unlike linear barcodes, stacked codes are read by a laser rather than an optical scanner.

What are the benefits of barcodes?

- Less expensive - barcodes are more affordable than RFID tags. when a a company uses both barcodes and RFID tags. when a company uses both barcodes and RFID tags, it can provide value where and when it's needed by using both solutions, as needed, without breaking the budget. Barcodes and RFID tags work well with existing technology, so companies with existing warehouse management systems can use this technology without having to re-enter information or purchase new software.

- Flexibility of surface composition - unlike RFID, barcodes can be affixed to most surfaces without affecting their performance. Metal, plastic, glass, etc. doesn't affect the barcode read. In addition, the surface can either be flat or curved.

- Durability - barcode tags can be made out of a variety of different materials to withstand whatever environmental conditions the barcode tag needs to resist.

What are the benefits of using barcode with RFID?

- Time savings - RFID readers can also scan barcodes. This means that if you're already using barcodes, you don't have to purchase new scanners. If you already have new barcode readers, you can still incorporate both technologies into one tag; however, it's critical that you keep the assets' location information in sync; some enterprise software systems can help address this issue.

- A more complete view of the supply chain - many companies currently use a mix of both technologies, and the coexistence of barcodes and RFID can provide the best of both worlds. To achieve this, you need to understand the characteristics of barcodes and RFID, how they work and what they can do. By understanding how each technology works, companies can make informed decisions about which technology to use in specific locations or processes.

When products are scanned using both technologies in the tag, for example, the system can more efficiently track and monitor their products as they move through the supply chain, from beginning to end. This can improve visibility and efficiency throughout the supply chain.

Flexibility - using a joint RFID-barcode solution allows for either data redundancy by programming the same information

Using barcode and/or RFID in a manufacturing

setting provides many benefitsinto the RFID tag as what the barcode reads or increasing the data capacity by programming different information into the RFID tag as what the barcode reads.

- Security - using both barcodes and RFID tags can provide higher levels of security. RFID tags are more difficult to copy and are more secure than barcodes; therefore, when a company uses both barcodes and RFID tags, it can provide a higher level of security with RFID tags, where required, without having to completely convert its entire system.

- Less disruption to operations and the supply chain - a joint RFID-barcode system can help create a more seamless process for companies that are automating their processes for product identification, shipping and tracking. For example, if a company uses barcode tags in addition to RFID tags, then the company can easily transition to using only RFID tags when the time is right, instead of trying to implement a huge process change all at once. For example, adding the printed barcodes to RFID tags on products can enable the transition to RFID and avoid unnecessary supply chain disruption.

- Easier transitions to RFID - if you need to transition to RFID more slowly due to financial considerations, gradually implementing and RFID solution alongside a barcoding system can save money and prevent disruption.

| About the Author: Marianne AlvaradoMarianne Alvarado is our Vice President of Sales. Alvarado joined Metalcraft in March of 2000 as a Territory Specialist, became Sales Manager in January 2022 and was named Vice President of Sales during August of 2023. She leads both the Outside and Inside Sales teams. Marianne lives in Davenport with her husband, Dave Beeman. Mobile Phone: 641-529-9492 Email: [email protected] Office: 3360 9th St. SW, Mason City, IA 50401 Office Phone: 641-423-9460 |