What are the different types of RFID inlays?

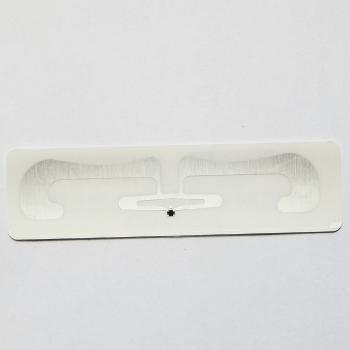

RFID inlays come in various types, each designed to suite different applications and environments. One common classification distinguishes between wet and dry RFID inlays based on their adhesive properties. Wet RFID inlays feature an adhesive backing, enabling immediate attachment to surfaces like packaging or products without additional processing. Conversely, dry RFID inlays do not have adhesive and are typically supplied on a carrier substrate, offering flexibility for custom integration methods such as embedding or lamination.

embedding or lamination.

Another categorization is based on frequency, with options including low-frequency (LF), high-frequency (HF), and ultra-high-frequency (UHF) RFID inlays, each suitable for different ranges and data transfer speeds.

Additionally, inlays vary in form factors, antenna designs, and encapsulation materials, allowing for tailored solutions across industries ranging from logistics and retail to healthcare and manufacturing. Selecting the appropriate type of RFID inlay involves considering factors such as adhesion requirements, integration complexity, application environment, deployment speed, and cost considerations.

What is the difference between wet or dry inlays?

RFID inlays are embedded in a substrate with an adhesive backing, making them ready for direct application onto surfaces such as packaging or products. These inlays are typically used in applications where immediate adhesion is necessary, enabling seamless integration into various materials.

On the other hand, dry inlays do not have adhesive backing and are often supplied on a carrier substrate. They require additional processing, such as lamination or embedding, to affix them onto surfaces effectively. Dry inlays provide more flexibility in application methods and are commonly used in situations that require customized integration or embedding within specific products or materials.

Should you use a dry inlay or a wet inlay for your RFID application?

Choosing between a wet RFID inlay and a dry RFID inlay depends on several factors specific to your application.

- Adhesion Requirements: If you need immediate adhesion to surfaces such as packaging or products without additional processing, a wet RFID inlay with its adhesive backing would be suitable. On the other hand, if you require flexibility in how the RFID tag is integrated or embedded into materials, a dry RFID inlay might be preferable.

- Integration Complexity: Consider the complexity of integrating the RFID tags into your products or materials. Wet RFID inlays are simpler to deploy as they come pre-attached with adhesive backing, while dry RFID inlays provide more flexibility for customized integration methods.

- Application Environment: Evaluate the environmental conditions in which the RFID tags will be used. Wet RFID inlays may be more suitable for applications where exposure to moisture or humidity is a concern due to their immediate adhesion properties. Dry RFID inlays might be preferred for applications where precise placement or embedding within specific materials is necessary.

- Deployment Speed: If you require rapid deployment of RFID tags onto surfaces, wet RFID inlays offer the advantage of quick application. However, if you have the time and resources for additional processing steps, such as lamination or embedding, dry RFID inlays provide more flexibility in deployment methods.

- Cost Considerations: Compare the costs associated with both types of inlays, including any additional processing or integration expenses. Wet RFID inlays may incur higher initial costs due to their pre-attached adhesive backing while dry RFID inlays might require additional materials and labor for integration but could be more cost-effective in certain scenarios.

By considering these factors and assessing your specific application requirements, you can determine whether a wet inlay or a dry inlay is the best choice for your needs.

Does Metalcraft use wet or dry inlays?

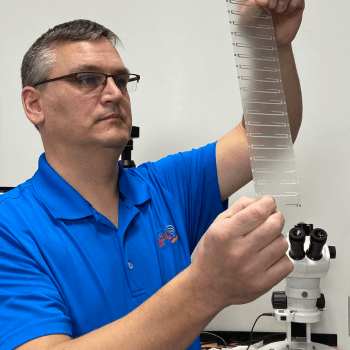

Most Metalcraft RFID tags can be made using either a wet RFID inlay or a dry RFID inlay. There are several factors to look at when deciding which type of inlay to use. For example, the RFID tag manufacturing process may require one type of inlay versus another. Additionally, another potential deciding factor is inlay availability from the manufacturer, i.e., a particular inlay is only produced one way or another.

For more information on wet/dry inlays, contact one of our RFID specialists at 800-437-5283 or [email protected].

| About the Author: Aaron HobertAaron Hobert is our RFID Technical Specialist. Hobert joined Metalcraft in September of 1994 as a Litho Press Operator, became the Autograph Team Lead in 1998 and in April 2005 he became the RFID Sales Support Rep. He was named our RFID Technical Specialist in 2008. Aaron lives outside Charles City with his wife Diane. Mobile Phone: 641-330-2660 Email: [email protected] Office: 3360 9th St. SW, Mason City, IA 50401 Office Phone: 641-423-9460 |