For modern manufacturing processes, product traceability and accuracy are critical. And companies are facing increased pressure to streamline their manufacturing processes to ensure accurate and on-time product deliveries. This means implementing solutions that give immediate data insights as most manufacturing facilities transition to Industry 4.0. Metalcraft has partnered with many manufacturers for everything from asset tracking and tracing to managing work in process conveyor belt efficiency, and we have our hands in the future as this industry adapts and transitions to 4.0.

An example of our next-gen technology is that with RFID-enabled asset management, you can auto-fill tracking information quickly on asset arrival without the need for any human intervention. This can theoretically happen at as many locations as you need per the application. By auto-filling information and delivery statuses, RFID eliminates both the labor requirements and human error possibilities of other forms of tracking while increasing production visibility and inventory accuracy.

No matter what, you want to know you have Metalcraft engineers by your side as we provide cost-effective ID technologies that:

- Keep track of inventory automatically

- Receive and assign goods, knowing where everything is

- Reduce unnecessary equipment purchases and incorrect deliveries

- Discourage theft and counterfeiting

- Provide real-time data on where every tracked device is

- Create supply-chain process optimization and transparency

- Provide a real-time account of safe handling

As we help manufacturers automate their processes, we’re partnering to best understand their unique applications and how we can help optimize their supply chain with solutions that give real-time results. And if there isn’t an “off the shelf” solution, we are known for our customization, being the first company to offer customizable RFID inlays, as one example. Now that’s ID Made Better®.

A versatile and affordable RFID tag made in the USA to fit a wide array of on-metal and standard applications, the Universal MC RFID Tag is available both preprinted and onsite printable to handle whatever asset tagging application you have.

The perfect solution for tracking assets on metal or non-metal surfaces that do not allow for attachment directly to the asset. The construction protects the inlay from environmental conditions that could affect the performance of the RFID tag.

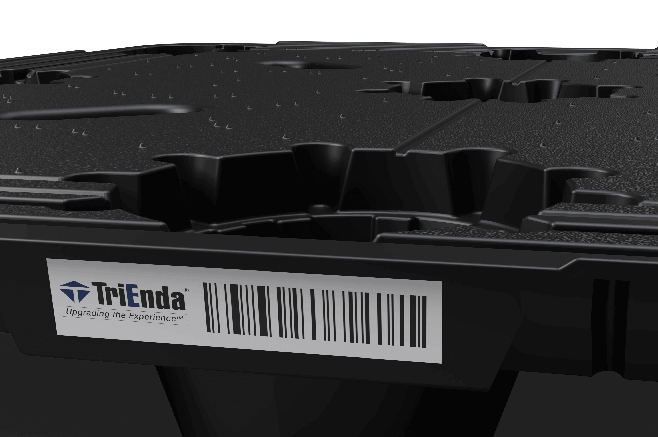

Perfect for tracking returnable containers such as pallets, crates or totes, Metalcraft’s Standard RFID Tag attaches directly to non-metal assets.

An RFID tag that truly lives up to its name. The Universal RFID Hard Tag features surface-independent tags with a patented inlay design used to obtain excellent read ranges regardless of the surface – metal, plastic, even wood.

The only thing “mini” about this tag is its size! With a smaller footprint and lower profile, the Onsite Printable Universal Mini RFID Tag easily fits where other tags may be too large and obtrusive and still gives incredible read ranges compared to other tags in its class.

The Universal Micro RFID Tag measuring 1 7/8” x 5/8” is a great solution to your identification projects that require the smallest RFID tag with great read range.

If you are looking for a small RFID tag, the Universal Mini RFID Tag is the one for you! The Universal Mini RFID Tag may be small in size, but it packs a powerful punch! Its compact design and slim profile make it ideal for spaces where larger tags would be cumbersome.

The closest thing you will find to a "one-size-fits-all” RFID solution!

From The Asset Tracking Blog

Metalcraft Explores Growing RFID Market

Metalcraft President Kyle Bermel sits down with Label & Narrow Web Magazine to discuss how different market segments can benefit from RFID technology and how Metalcraft is up to the challenge.

What is the Best Solution for Asset Tracking in Manufacturing?

What is the best solution for asset tracking in manufacturing? Read our latest article to learn how to determine what identification products in your asset tracking solution in manufacturing.

RFID in Manufacturing: A Formula for Success

The potential applications for manufacturing are seemingly endless. Check out our latest blog to see why now is the time to evaluate RFID technology for your manufacturing company.

Manufacturing - RFID Case Studies

Protecting Pallets

When customers wanted to make their systems smarter by incorporating RFID technology, TriEnda teamed up with Metalcraft to offer RFID as a standard product, making it easier to track returnable containers.

Weighing The Benefits Of RFID

Rusty's Weigh Scales, Metalcraft Partner To Provide Complete Solution to Customers

Creating efficiencies is a primary benefit of implementing systems using radio frequency identification (RFID) technology in any industry for a wide variety of applications – even some that may surprise you.

Automotive Supply Chain Moves Better with RFID Packaging

Universal RFID tags track $27 million packaging in closed loops