What is an RFID Tag?

RFID stands for Radio Frequency Identification. An RFID tag is a small electronic device that consists of an RFID chip (microchip) attached to an antenna. These tags can be attached to or embedded in various objects, products, or animals for identification and tracking purposes.

How do RFID Tags work?

RFID systems are made up of three main components: tags, readers and middleware.

RFID Tags are essentially small memory banks, storing bits of valuable information that can be used for asset management and a variety of other purposes. They use radio waves to communicate with nearby readers, sending over portions of identifying data. The information stored in RFID stickers can range anywhere from a single serial number to multiple pages of data.

RFID tag readers, on the other hand, are basically the other end of the information exchange. They are what we use to take those radio waves from the tags and translate them back into useful data. RFID tag readers are devices with one or more antennas that can emit their own radio waves and scan the signals of any RFID tags within range.

RFID tag readers offer some versatility depending on the needs of your application. You can have mobile RFID readers that you can carry around in your hand to scan tags, or they can be mounted in a single location to scan tags that enter their proximity. RFID readers can even be built into existing architecture like a cabinet or doorway.

Middleware serves as the essential interface between the reader and your company databases and information management software. Not only does middleware handle communication between the reader and your existing systems, but it also helps to filter, aggregate and interpret all of that data coming from the RFID tags.

What Types of RFID Tags are There?

In the ultra-high frequency subset of RFID systems, you have three different types of RFID tags: active, passive and semi-active. This mainly has to do with the style of the tag.

Active RFID Tags

Active RFID tags are the most complex of the different types of RFID tags. They are powered by their own batteries and have an integrated circuit, antenna and onboard transmitter.

With their own battery, active RFID tags can support additional features and functionality, such as integrated sensors or increased memory and logic. The onboard transmitter also allows these tags to work over greater distances. They allow the RFID tags to send energy directly to the reader rather than just reflecting back energy that the reader transmitted to the RFID tag, thus increasing the read range.

The cost of this added functionality is that active RFID tags take up more space than their passive or semi-active counterparts. Active RFID tags also literally just cost more. Since they are battery-operated, you can expect these RFID tags to have shorter lifespans as well. As such, active RFID tags are often too cost-inefficient and overly complex for most operations.

Passive RFID Tags

Unlike active RFID tags, passive RFID tags are typically comprised of only an integrated circuit and an antenna. They do not have a battery and must instead be powered by the reader through inductive coupling when dealing with high frequencies, or through backscatter if you’re working with ultra-high frequencies.

Since they don’t have their own battery, passive RFID tags can only “run” when needed, leading to energy savings and extending their lifespan. It’s also easier to reprogram passive RFID tags, leaving the serial number the same and changing whatever data you need to alter on the backend. They’re also easier to incorporate into your operations with the help of an RFID expert.

However, that simplicity does carry over into function as well. Passive RFID tags don’t have the increased read ranges of active RFID tags or the ability to add on as many bells and whistles. This makes passive RFID tags the perfect choice for most applications that only require intermittent check-ins at certain points, but not a great choice for more demanding applications that require constant tracking in real-time.

Semi-Active RFID Tags

Semi-active RFID tags, also sometimes called semi-passive RFID tags, are a bit of a compromise between the two. They are made up of an integrated circuit, an antenna and a battery.

By having their own battery, semi-active RFID tags allow for the additional device functionality like active tags, including sound notifications or real-time tracking. However, without an onboard transmitter, they gain no benefit in terms of read range, and their battery puts them in the same category as active tags for their decreased lifespan.

What are the advantages of RFID technology?

Choosing to go with RFID technology over manual asset management or other auto-ID technologies comes down to performance, efficiency and reliability. Here are some of the top advantages to RFID technology:

Higher ROIs

For many applications and use cases, RFID tracking implementation can lead to a significant ROI. This is, of course, dependent on the specific needs of your application.

Environmental constraints, asset compositions and read range limitations/requirements can all impact how effective – and thus cost-efficient – an RFID system is for your application. While RFID is considered the latest and greatest evolution in asset management, it just may not be right for every application, especially if you’re expecting a certain ROI in a specific time window.

That’s why Metalcraft has the DART™ Qualification Process, to ensure that RFID technology is the right choice for a specific operation and that expectations are clear from the very beginning. By defining what you want to accomplish and your expected outcome, then comparing that to the requirements of your system, Metalcraft can make sure that you make the right choice.

operation and that expectations are clear from the very beginning. By defining what you want to accomplish and your expected outcome, then comparing that to the requirements of your system, Metalcraft can make sure that you make the right choice.

Fast Tracking and Better Asset Management

One of the biggest operational benefits of RFID technology is the ability to read multiple tags at once. Rather than having to scan each barcode individually, taking the time to line the label up with the scanner, RFID works on proximity, allowing you to read a case lot of containers or pallets in a fraction of the time.

By instantly detecting assets upon arrival and pairing them with information in your database, RFID tracking systems can better manage your assets than ever before. With RFID technology, you can easily cross-reference your inventory against assigned locations – both stationary and mobile – to see if certain assets are present, missing or in transit. This allows you to not only make sure that everything is running on schedule, but also pinpoint where an asset was lost if anything goes missing.

Reduced Human Error and Labor

With the automatic nature of RFID tracking systems, human error is almost entirely eliminated. So long as the tags are within range of the reader, and there is no outside interference from the environment, RFID technology reliably tracks your assets every time.

RFID-enabled asset management also requires far less labor than manual or barcode-only checks. Especially with higher-end RFID tags and fixed readers, RFID asset management is the closest thing to a fully automated tracking solution.

Easy Integration and Upgrades

RFID technology can work with many existing systems, allowing you to easily integrate RFID systems into your supply chain. You can also choose to adopt RFID technology at certain locations to begin with, then add on additional locations at your own pace.

Data Redundancy

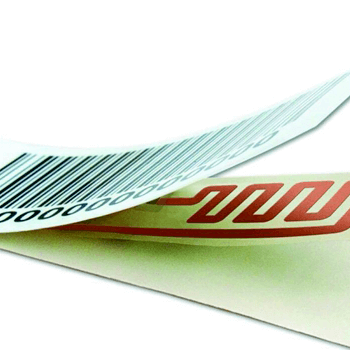

While RFID technology offers benefits beyond barcodes and typical auto-ID technologies, it’s usually not an either-or scenario. In fact, using both barcodes and RFID systems in your asset management can help with data redundancy.

Once you have an RFID system set up, minimal investment is needed to add a barcode to an RFID tag. If you’re tracking mobile assets moving between facilities, barcodes can act as redundant technology, allowing you to read tags in an open-source system wherever there is no RFID-supported infrastructure. Having the barcode information programmed into the RFID chip can also add extra redundancy for peace of mind.

How can RFID Tags be used?

RFID tags have a wide range of applications across various industries due to their ability to uniquely identify objects and facilitate data exchange wirelessly. Here are some common ways RFID tags can be used:

Inventory Management: RFID stickers are widely used in retail and warehouse settings to track inventory levels automatically. RFID tags can be attached to products, and RFID tag readers can quickly scan items without requiring line-of-sight, allowing for faster and more accurate inventory management.

RFID Tags can be used in retail/warehouse settings to track inventory levels automatically. - Supply Chain Tracking: RFID tags can be used to track items as they move through the supply chain. From manufacturing facilities to distribution centers to retail stores, RFID technology provides real-time visibility into the movement of goods, helping to streamline logistics and reduce errors.

- Asset Tracking: Many organizations use RFID tags to track and manage valuable assets such as equipment, tools, vehicles, and IT assets. By affixing RFID tags to assets, businesses can easily locate and monitor their assets, reducing loss and improving asset utilization.

- Access Control: RFID tags are commonly used for access control in buildings, parking lots, and events. Employees or authorized individuals can use RFID-enabled cards, smartphones, or wearables on a compatible reader. This provides a convenient and fast payment experience.

- Contactless Payments: RFID technology is used in contactless payment systems, allowing consumers to make purchases by simply tagging their RFID-enabled cards, smartphones, or wearable on a compatible reader. This provides a convenient and fast payment experience.

- Medical and Healthcare Applications: RFID tags are used in healthcare settings for patient identification, inventory management of medical supplies, tracking of medical equipment, and monitoring the temperature of sensitive medications and specimens.

- Anti-counterfeiting: RFID tags can be integrated into products to authenticate them and combat counterfeiting. By scanning the RFID tag, consumers, retailers, and authorities can verify the authenticity of products and ensure they are genuine.

These are just a few examples of how RFID tags can be used. The versatility and scalability of RFID technology make it applicable to a wide range of industries and use cases, offering benefits such as improved efficiency, enhanced security, and better asset management.

For more information about RFID tags and how they can be used please contact Metalcraft for a quick quote or to receive FREE samples.

| About the Author: Aaron HobertAaron Hobert is our RFID Technical Specialist. Hobert joined Metalcraft in September of 1994 as a Litho Press Operator, became the Autograph Team Lead in 1998 and in April 2005 he became the RFID Sales Support Rep. He was named our RFID Technical Specialist in 2008. Aaron lives outside Charles City with his wife Diane. Mobile Phone: 641-330-2660 Email: [email protected] Office: 3360 9th St. SW, Mason City, IA 50401 Office Phone: 641-423-9460 |