There is so much variety to be had with plastic barcode labels. Applications include labels for windshields, cables, containers, racks, destructible, metalized, tamper evident and so much more! All feature superior readability and most can be customized to your environment. This is truly your hardworking label that looks great, conforms to any surface and can be stylized with four-color process as well as PMS colors for brand impact. Our options are endless as anything can be customized. That’s ID Made Better®.

EZ-Peel Barcode Labels enable the user to reposition or take off the tiny barcode label without leaving any adhesive residue behind.

Metalcraft’s Removable Paint-Mask Barcode Labels have a unique one-time removable paint-mask.

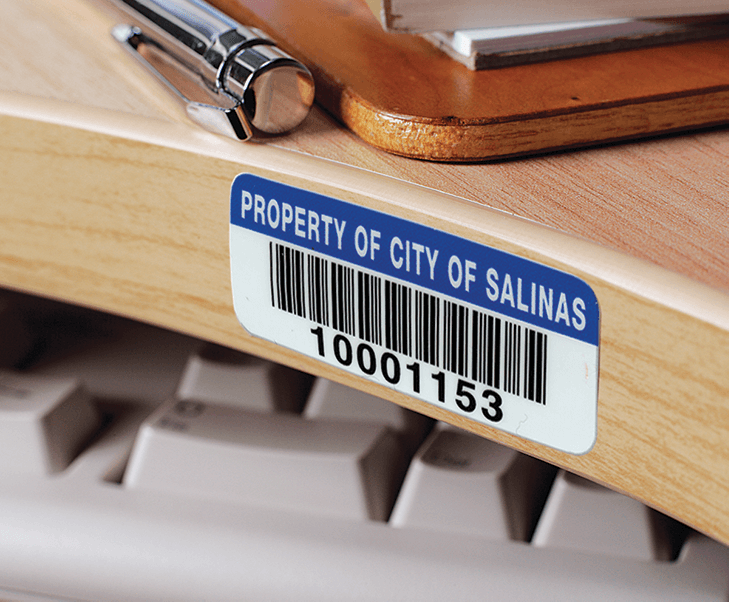

An ideal solution for indoor asset tracking, “VALUMARK” Labels are an effective and affordable identification solution.

Metalized Silver Polyester Labels have the appearance of metal without the accompanying price tag.

Metalcraft’s Premium Polyester Barcode Labels provide both flexibility and functionality for your asset tracking needs.

Make it easy on yourself with easy-to-mark Barcode Cable Labels from Metalcraft.

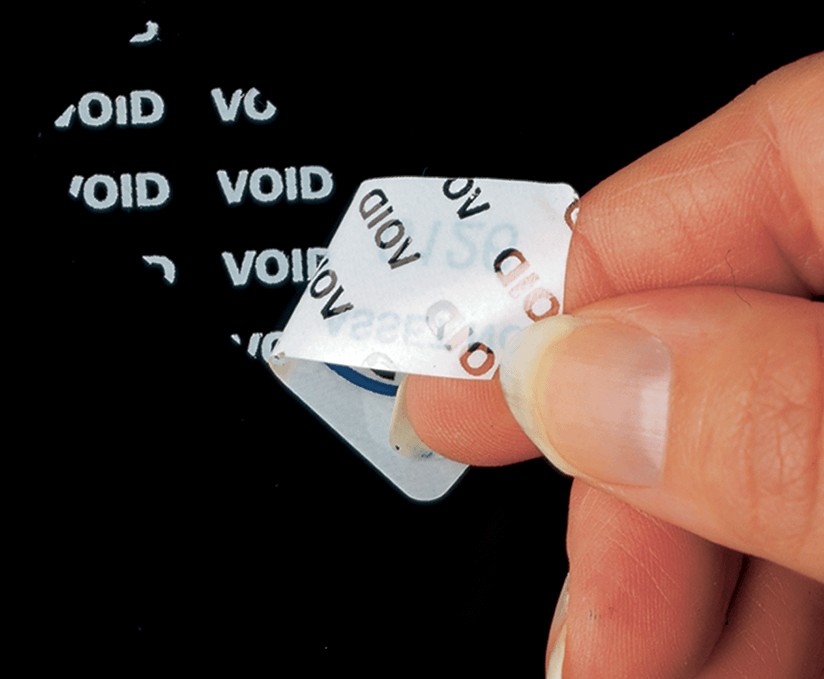

Secure valuable assets and deter theft with Metalcraft’s Security Barcode Labels!

Discourage theft and keep your property intact with Metalcraft’s Tamper-Evident Barcode Labels.

Metalcraft’s Premium StyleMark Labels use a flexible polycarbonate material with a textured, non-reflective finish.

Our CRAFTMARK Polyester Barcode Labels are printed using our thickest polyester and a .0035” thick adhesive.

Gain the advantage for your asset tracking solution with Metalcraft’s ID Advantage Barcode Labels.

Metalcraft's Windshield Tags offer a more accurate and secure way to allow access into various locations.

Warehouse Rack Labels keep your dynamic warehouse environment organized and efficient.

Metalcraft Long Range Barcode Labels are an easy way to keep track of your warehouse inventory from a distance.

What are some common features of plastic barcode labels?

Some common features of custom barcode labels include:

- Durability - polymer materials such as polyethylene, polypropylene or polyester make plastic barcode labels durable and resistant to moisture, chemicals and temperature fluctuations

- Adhesives - plastic barcode labels typically come with an adhesive that works well on a variety of different surfaces, including curved or uneven surfaces

- Customizability - customers can customize what is printed on the label - including the barcode symbology

- Affordability - plastic barcode labels are often cost-effective and can be produced in large quantities, making them an economical option for many organizations

What are some common applications for plastic barcode labels?

Custom barcode labels have a wide range of applications across various industries including:

- Inventory management - plastic barcode labels are commonly used in warehouses and distribution centers for tracking and managing inventory. Each item is assigned a unique barcode label, which is scanned using a barcode scanner to update the inventory database.

- Asset tracking - custom barcode labels can be used to track and manage fixed assets such as computers, equipment, and furniture. Each asset is assigned a barcode label, which is scanned to track its location and movement.

- Retail and logistics - plastic barcode labels are commonly used in retail and logistics operations to track and manage shipments, as well as to scan and track products at the point of sale.

- Identification and access control - custom barcode labels can be used for identification and access control purposes, such as in membership cards, ID badges, and access control cards.

From The Asset Tracking Blog

A Comprehensive Guide to Asset Tracking Technologies

The choice of asset tracking technology depends on various factors. Check out this article to learn about some of the common asset tracking technologies and their key features.

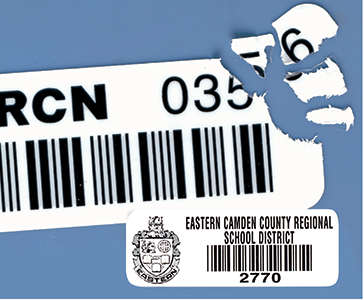

Asset Tracking in Education

In our latest industry sourcebook - Solutions for Education - you will find valuable information on asset tracking in schools as well as real-world case studies from our customers.

Introduction to Barcode: 1D and 2D Barcode Symbologies

Barcodes come in many forms, but do you know how a barcode works? Our introduction to barcodes spells out the basics to help you make the best choice for your application.

Plastic Barcode Labels Case Studies

A Really "Cool" Application

Background

The next time you stop at a convenience store for a cool, refreshing drink, check to see if there is a Frazil machine and treat yourself to this tasty concoction. Frazil, aka "the greatest slush on Earth," is made by Salt Lake City, Utah-based Freezing Point.

School Asset Tracking Makes Good "Cents"

Calhoun County School District partners with Metalcraft to track district-wide assets.

Head Of The Class

A great partnership stands the test of time. Learn about how Bar|Scan, Inc. partnered with Metalcraft to provide Wake County Public School District with an asset tracking solution.