Metalcraft's durable RFID tags have revolutionized the way companies track and manage assets in a variety of industries. Combining the power of RFID technology with exceptional durability, Metalcraft's RF identification tags offer a reliable and efficient solution for inventory management, supply chain optimization, and asset tracking.

Designed to withstand harsh environments and rough handling, durable RFID asset tags provide organizations with unparalleled visibility and control over their valuable assets. With their robust construction and long-lasting performance, these tags have become an indispensable tool for enhancing operation efficiency and driving business success.

Once we've worked with you to identify that RFID tracking is the right solution for your application, our wide breadth of product offerings can be customized to meet the task at hand. For any application, we offer the most durable, technology-agnostic solutions coupled with an unmatched selection of adhesives. We are the perfect RFID company for your needs.

Explore RFID Tags

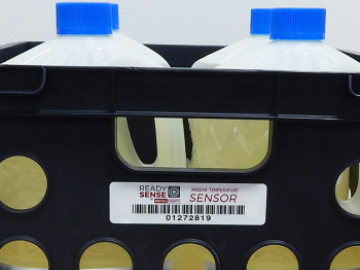

Our line of durable on-metal RFID tags and labels are perfect for your metal surface application projects. Designed to work on a variety of metal surfaces, our on-metal RFID tags work well for asset tagging, work-in-process and returnable container applications.

Our RFID tags for glass offer specialized inlays to be read through windshields and more, providing a read range of 18+ feet. We also offer a removable adhesive, perfect for those times you need a “temporary” tag - whether it’s for rental cars, rental equipment or controlling

For items like plastic bins, crates and more, our variety of RFID tags can conform and provide durability, security and be tamper-proof for anti-theft RFID applications. For example, our RFID pallet tags for plastic pallets stay put under extraordinary cond

Our Stick and Staple RFID products are ideal for applications involving hard-to-adhere surfaces (pallets, crates, barrels)with the tag’s construction protecting the inlay.

For wristbands, racebibs or credential tags, the added element of people wearing RFID solutions means color, performance but low-profile. Check out our customizable solutions for trackable, company branding.

For bales, key fobs or general hanging tags, we have RFID products that are durable, removable and reusable. Our tag’s polymer construction protects the text and RFID inlay from the elements, offering superior access control and tracking.

RFID can be used for so many different applications, like even measuring temperatures as they fluctuate or moisture levels. This can be critical for certain applications where steady levels need to be maintained. So how does this work?

From The Asset Tracking Blog

Beyond RFID Tags: Top Questions About RFID Technology

We answer your top questions about RFID technology, including its definition, inventory management and cost.

What is an RFID Tag and what are they used for?

What is an RFID tag and what are the applications for one? This article answers some common questions we receive about RFID technology.

Cheap RFID Tags (and why they may not be as cheap as you think)

Everyone wants a cheap solution to their RFID tracking application, but cheap RFID tags often come up short of meeting expectations.

Unlock Efficiency and Savings: the Ultimate Guide to IT Asset Tracking

This resource answers many questions about IT asset tracking and provides real-world customer success stories about their IT asset tracking applications.

Download Now

Case Study

Creating a Memorable "Experience"

Read Case Studyeshots and Metalcraft partner to help military recruits discover career opportunities

What are RFID Tags?

Radio Frequency Identification, or RFID, refers to a technology where information is transmitted wirelessly over radio waves. RFID tags and labels have 3 main components:

• IC (integrated chip) which executes commands and stores data

• Antenna which absorbs RF waves and helps broadcast the signal

• Substrate (polyester, paper, etc.) which is the material that the chip and antenna are attached

How do RFID Tags work?

RFID tags work by sending and receiving information through an antenna and an attached microchip or integrated circuit. An RFID reader, a device that can generate and read the information on radio waves, is used to communicate and interact with the RFID tag. These RFID readers can both read and write to the memory on the RFID tag's microchip. This means different pieces of data (unique identifying numbers, serial numbers, etc.) can be read and written onto the tags, which can be attached to any item or product for easy tagging and tracking. Download our handbook for more.

What are the types of RFID asset tags?

There are two primary categories of RFID asset tags: tags with batteries and tags without batteries. Tags with batteries are called battery assist or active RFID tags. Battery enabled RF tags incorporate a battery as a power supply or to supplement the power provided by the RFID reader.

Passive RFID asset tags do not use a battery and instead works by using electromagnetic energy transmitted from the RFID reader. When a passive label is read/scanned by an RFID reader it is energized (interrogated) by the radio waves coming from the reading device. The energy received from the radio waves are received via antennas attached to the passive tag's chip which powers the chip and responds to the reader all in a matter of milliseconds.

What is the difference between an RFID "tag" and an RFID "inlay?"

An RFID tag is a small electronic device that contains a unique identifier and is used for tracking and identification purposes. The construction of an RFID tag typically consists of three layers. The first layer, known as the substrate, is the material on which information can be printed. This layer provides a surface for the RFID inlay to be attached to.

The second layer is the actual RFID inlay, which contains the electronic components that allow the tag to communicate with RFID readers. This inlay is usually made up of a microchip and an antenna, which work together to transmit and receive data.

The last layer of the RFID tag is the attachment adhesive, which is used to securely attach the tag to an object or surface. This adhesive layer is crucial for ensuring that the tag remains in place and can withstand various environmental conditions.

Overall, the construction of an RFID tag is designed to be durable, reliable, and efficient in order to accurately track and identify items in a variety of applications.

The RFID inlay is a crucial component of the RFID tag, serving as the brain and communication hub of the entire system. It is made up of three main parts: the integrated circuit (IC), antenna, and substrate.

The integrated circuit is where the data is stored and processed, allowing the tag to communicate with RFID readers. The antenna is responsible for transmitting and receiving radio frequency signals, enabling the tag to be detected and read from a distance. The substrate provides support and protection for the IC and antenna, ensuring the inlay remains durable and functional in various environments.

Together, these components work seamlessly to enable the RFID tag to track and identify items in a wide range of applications, from inventory management to access control.

What is a passive vs active RFID tag?

Passive and active RFID (radio frequency identification) tags are two types of RFID technology used for tracking and identifying objects. There are several differences between the two types of tags. Active RFID asset tags have their own battery which allows them to transmit signals without relying on an external energy source.

Conversely, passive RFID asset tags do not have their own power source. They rely on the energy emitted by the RFID reader to transmit their data. Active RFID tags have a much longer read range than their passive counterpart and typically cost more than passive tags. In addition, active tags are typically larger than passive tags due to the inclusion of their battery. Lastly, active tags have a shorter lifespan due to its battery than passive tags. The choice between passive and active RFID tags should depend on the specific requirements of the application. For more information or to get a quote please contact us at 800-437-5283 or [email protected].