The Metalcraft Advantage

Find Your Solution By Application

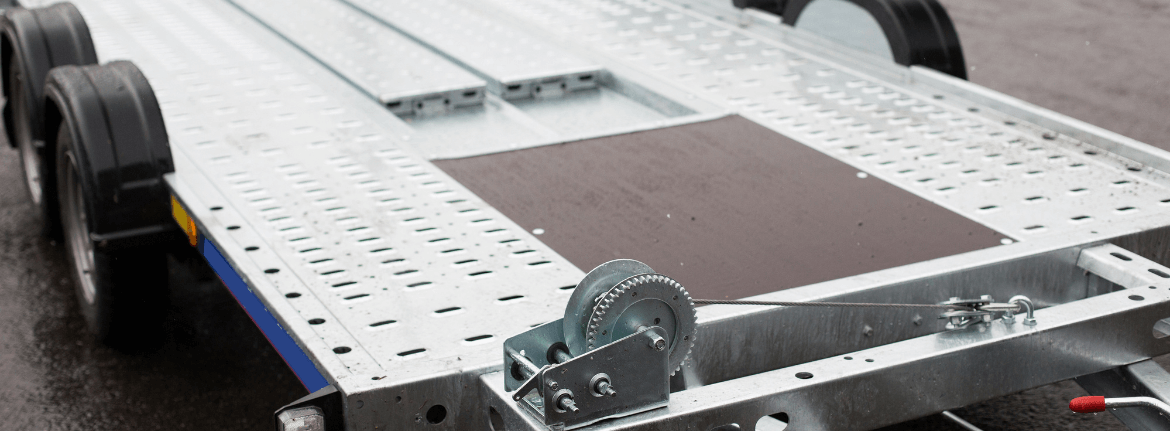

Case Study

Durable Tags Never "Trail" the Competition

Signature Nameplates lead to strong product identification solution for trailer manufacturers

Find your Solution by Industry

We deep dive into our customer's business to develop innovative solutions for their unique needs, in any industry, with any technology.

Explore Industry SolutionsBarcode vs RFID Handbook

Choosing to go with RFID technology over barcoding for asset management comes down to performance, efficiency and reliability. Neither barcode nor RFID is better than the other in all scenarios. You have to pick the right technology for your application needs. Download the handbook to learn:

- Benefits of Asset Management

- Advantages of Barcode

- Advantages of RFID

- Metalcraft Advantage

From The Asset Tracking Blog

Beyond RFID Tags: Top Questions About RFID Technology

We answer your top questions about RFID technology, including its definition, inventory management and cost.

Read Blog

What is an RFID Tag and what are they used for?

What is an RFID tag and what are the applications for one? This article answers some common questions we receive about RFID technology.

Read Blog

Demystifying the RFID Inlay Manufacturing Process: From Concept to Card

Want to know how an RFID inlay is created? This article breaks down the process from designing to the finished product.

Read Blog