Having a tagging and tracking solution for your tools can help reduce loss and theft on site, keep a general inventory for re-orders and help you find what you need, when you need it. On top of that, making sure you’re successfully capturing data in extreme environments means needing a robust, reliable solution. Metalcraft is known for our products’ durability in the harshest of conditions—from high temperatures to abrasive/heavy impact situations, we have tool tracking solutions to stand up to whatever you (literally) throw at it. Now that’s ID Made Better®.

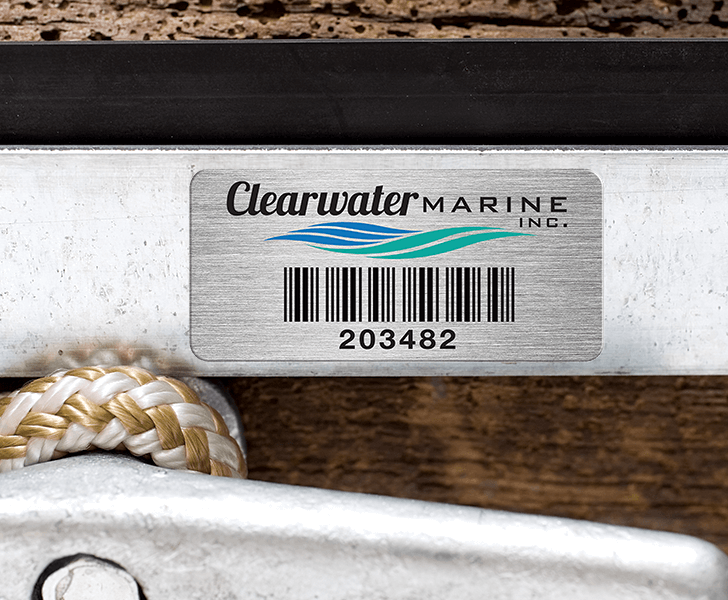

Metal Barcode Tags combine reliability with the durability you have come to expect with any Metalcraft product.

Tabbed Metal Barcode Nameplates have a convenient break-away tab to assist with liner removal.

Metalized Silver Polyester Labels have the appearance of metal without the accompanying price tag.

Metalcraft’s Foil 2D Dot is an ideal identification solution for small parts tracking.

Metalcraft’s Premium Polyester Barcode Labels provide both flexibility and functionality for your asset tracking needs.

The QuickTab Metal Asset Tag Dispenser is our patented product that makes metal nameplate application more efficient.

We’ve combined our Tabbed Metal Barcode Nameplate with a specially designed metal cable to provide a more automated process for applying adhesive-backed nameplates.

Our flexible Foil Barcode Labels conform to surfaces while withstanding chemicals, abrasion, solvents and high temperatures.

Make it easy on yourself with easy-to-mark Barcode Cable Labels from Metalcraft.

Metalcraft’s Premium StyleMark Labels use a flexible polycarbonate material with a textured, non-reflective finish.

Our CRAFTMARK Polyester Barcode Labels are printed using our thickest polyester and a .0035” thick adhesive.

Gain the advantage for your asset tracking solution with Metalcraft’s ID Advantage Barcode Labels.

What is Tool Tracking?

Tool tracking typically refers to the process of monitoring and managing tools within an organization or a specific context. This can involve the use of technology, such as barcodes, RFID tags, or other tracking systems to keep tabs on the location, usage, and maintenance of various tools. The goal is to enhance efficiency, reduce loss or theft, and ensure that tools are available when needed.

In industrial or construction settings, tool tracking may involve software solutions that help organizations keep a detailed inventory of tools, track their movement between locations, and schedule maintenance or repairs. This can be particularly important for large organizations with extensive tool inventories, where effective tracking can lead to cost savings and improved productivity.

What are the benefits of Tool Tracking?

Tool tracking offers various benefits across different industries and organizational contexts. Here are some key advantages:

- Inventory Management - tool tracking systems help maintain accurate and up-to-date inventories. This ensures that organizations know what tools they have, where they are located, and how many are available for use.

- Cost Savings – efficient tool tracking can lead to cost savings by reducing the need for unnecessary purchases. Organizations can avoid overstocking or duplicate purchase when they have a clear understanding of their tool inventory.

- Productivity Improvement – by knowing the location of tools, employees can quickly locate and access the necessary equipment, reducing downtime and improving overall productivity.

- Prevent Loss and Theft – tool tracking systems help prevent the loss or theft of valuable tools. If a tool goes missing, organizations can quickly identify the last known location and take appropriate action to recover or replace it.

- Maintenance Scheduling – regular maintenance is crucial for extending the lifespan of tools and ensuring they function optimally. Tool tracking systems can automate maintenance schedules, reminding organizations when tools are due for inspection or repairs.

- Regulatory Compliance – in some industries, there are regulatory requirements related to tool maintenance, safety, and documentation. Tool tracking systems can help organizations comply with these regulations and maintain a record of inspections and repairs.

- Data-Driven Decision Making – tool tracking systems provide valuable data and insights into tool usage patterns, which can inform decision-making processes.

- Improved Safety – ensuring that tools are well-maintained and in good working conditions contributes to a safer work environment. Tool tracking helps organizations identify and address potential safety concerns promptly.

Overall, implementing a tool tracking systems can lead to more efficient operations, reduced costs, and increased overall effectiveness in managing tools within an organization.

What tags should you use for Tool Tracking?

Tags used for tool tracking play a crucial role in the effectiveness of the tracking system. The choice of tags depends on factors such as the type of tools, the working environment, and the desired level of automation. Here are some common types of tags used for tool tracking.

- Barcode Labels - cost effective, easy-to-print, and can be scanned with handheld barcode scanner

- QR Codes – can store more information than traditional barcodes, and can be scanned with smartphones

- RFID Tags – radio frequency identification (RFID) allows for non-contact reading

- Smart Labels – enables additional functionalities such as temperature monitoring, providing more comprehensive tool tracking

- Tamper-Evident Labels – labels designed to show evidence of tampering and enhances security and helps prevent unauthorized removal or transfer of tags

- Smart Labels – labels with integrated sensors or technology that enable additional functionalities such as temperature monitoring, providing more comprehensive tool tracking

- Durable Labels – labels designed for harsh environments that are resistant to wear, tear and exposure to environmental factors

When choosing tags for tool tracking, it’s essential to consider the working conditions, the required level of durability and the desired features. The selection should align with the specific needs and goals of the organization implementing the tool tracking system.

From The Asset Tracking Blog

Understanding 2D Barcodes

Check out this article to learn how 2D barcodes have revolutionized inventory management, product tracking, mobile payments, marketing campaigns and more.

Celebrate National Barcode Day June 26th

National Barcode Day commemorates June 26, 1974 when a clerk scanned a 10-pack of Wrigley's Juicy Fruit gum at an Ohio supermarket.

Even Ben Franklin Knew the Importance of Tool Tracking

RFID can not only help you manage your inventory of tools, but also help you track the tool condition and warranties.

Tool Tracking Case Studies

The Right Tool for the Job

Background

For more than 35 years, ToolHound has delivered a comprehensive portfolio of tool and equipment solutions for companies of all sizes across a variety of industries, including construction, power generation, chemical processing, mining and job site equipment maintenance and rental.

Staying Clean With Barcode Tracking

Tufts University relies on Metalcraft nameplates to serve 600 patients daily

The Challenge

Tufts University School of Dental Medicine in Boston combines education, research, patient care and community service to produce well-rounded dental professionals. They combine these disciplines at the Tufts Dental Clinics, offering a full range of high quality general, specialty, and emergency dental care at lower fees than private practices.