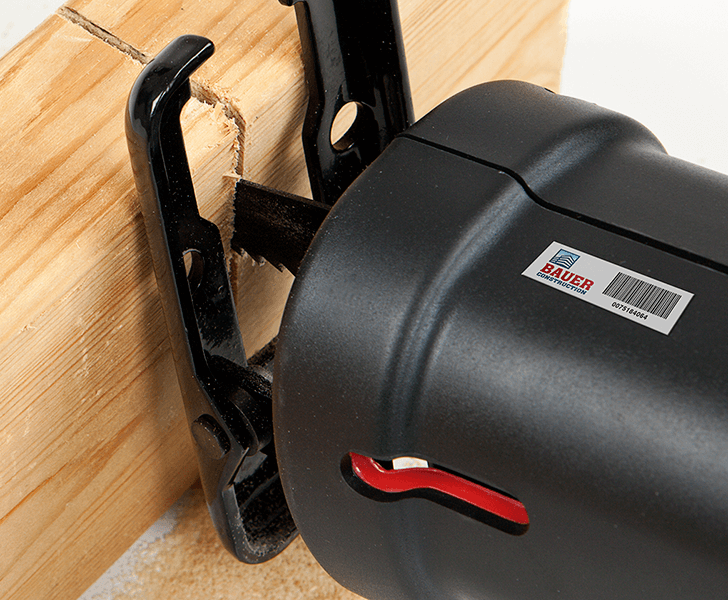

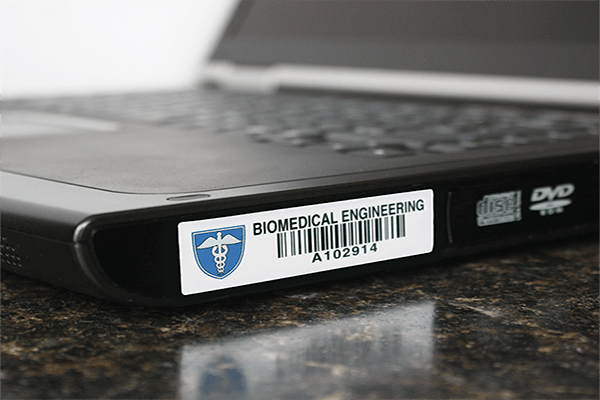

Having a tagging and tracking solution for your tools can help reduce loss and theft on site, keep a general inventory for re-orders and help you find what you need, when you need it. On top of that, making sure you’re successfully capturing data in extreme environments means needing a robust, reliable solution. Metalcraft is known for our products’ durability in the harshest of conditions—from high temperatures to abrasive/heavy impact situations, we have tool tracking solutions to stand up to whatever you (literally) throw at it. Now that’s ID Made Better®.

A versatile and affordable RFID tag made in the USA to fit a wide array of on-metal and standard applications, the Universal MC RFID Tag is available both preprinted and onsite printable to handle whatever asset tagging application you have.

The perfect solution for tracking assets on metal or non-metal surfaces that do not allow for attachment directly to the asset. The construction protects the inlay from environmental conditions that could affect the performance of the RFID tag.

Perfect for tracking returnable containers such as pallets, crates or totes, Metalcraft’s Standard RFID Tag attaches directly to non-metal assets.

The only thing “mini” about this tag is its size! With a smaller footprint and lower profile, the Onsite Printable Universal Mini RFID Tag easily fits where other tags may be too large and obtrusive and still gives incredible read ranges compared to other tags in its class.

The Universal Micro RFID Tag measuring 1 7/8” x 5/8” is a great solution to your identification projects that require the smallest RFID tag with great read range.

If you are looking for a small RFID tag, the Universal Mini RFID Tag is the one for you! The Universal Mini RFID Tag may be small in size, but it packs a powerful punch! Its compact design and slim profile make it ideal for spaces where larger tags would be cumbersome.

How do you do tool tracking with RFID?

Tool tracking with RFID (radio frequency identification) involves using RFID technology to identify and manage the location and status of tools. Here is a general guide on how to set up tool tracking with RFID:

- Define Requirements – identify the tools you want to track and the environment where the tools will be tracked

- Choose RFID Tags – determine whether to use active RFID tags or passive RFID tags for tool tracking, then select RFID tags suitable for your tools and environment

- Select and Implement RFID Infrastructure – choose RFID readers compatible with the selected RFID tags and install readers in strategic location where tools are expected to be tracked

- Tagging Tools – program each RFID tag with a unique number linked to the tool in the database and attach the RFID tag to respective tool

- Integration with Tracking Software – implement tracking software that interfaces with RFID readers and the database

- Establish Workflows – define workflows for tool check-in, check-out, and any other relevant activities and train staff

- Monitoring and Alerts – set up monitoring tools to track tool movements and usage patterns implementing alerts for any anomalies, such as unauthorized tool usage or missing tools

- Maintenance and Calibration – regularly maintain and calibrate RFID readers and tags to ensure accurate data capture

- Security Measures – implement security measures to protect RFID data and prevent authorized access

Remember that the effectiveness of RFID tool tracking depends on careful planning, proper implementation, and ongoing maintenance. It is also crucial to involve relevant stake holders and provide adequate training to ensure the system’s successful adoption.

From The Asset Tracking Blog

Metalcraft Explores Growing RFID Market

Metalcraft President Kyle Bermel sits down with Label & Narrow Web Magazine to discuss how different market segments can benefit from RFID technology and how Metalcraft is up to the challenge.

Metalcraft's RFID Tag Tops In Industry Reports Study

University of Texas at Arlington study confirms that an RFID tag from Metalcraft will perform reliably and accurately with better than average readability.

What is RFID? A Basic Guide to Radio Frequency Identification

Integrated chip ... antenna ... substrate .... these are all parts of what makes up and RFID tag. Our guide explains these components as well as takes a look at the different types of RFID tags.