RFID can make any WIP more agile and efficient, and with an almost endless list of potential applications, it’s a relief to have the RFID deep knowledge and expertise in your partner, Metalcraft. Working together, just like RFID and WIP, we can elevate your solution to one with benefits you may not have even thought of, custom-designed just for you….Now that’s ID Made Better®.

These .016” thick aluminum nameplates offer the greatest flexibility in nameplate design.

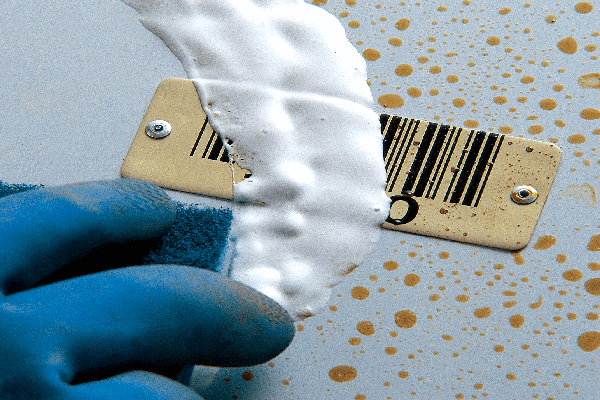

Teflon® Coated Nameplates are easy to clean, acid-resistant and temperature-resistant up to 500 °F.

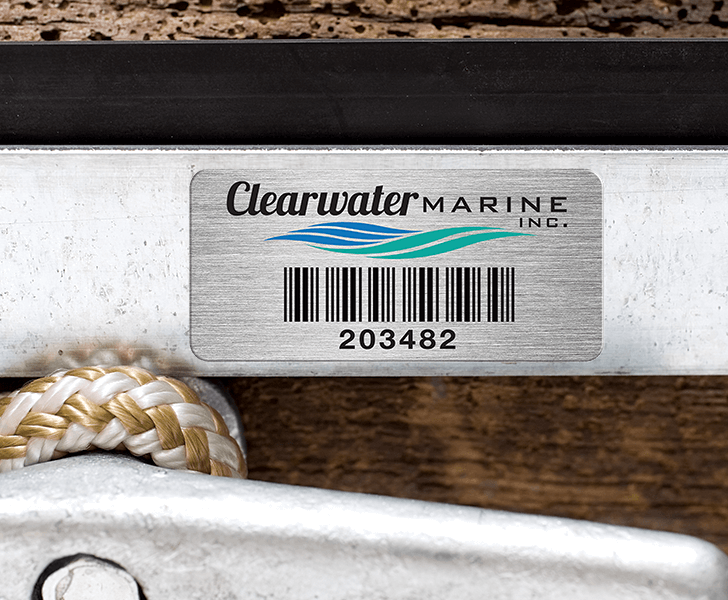

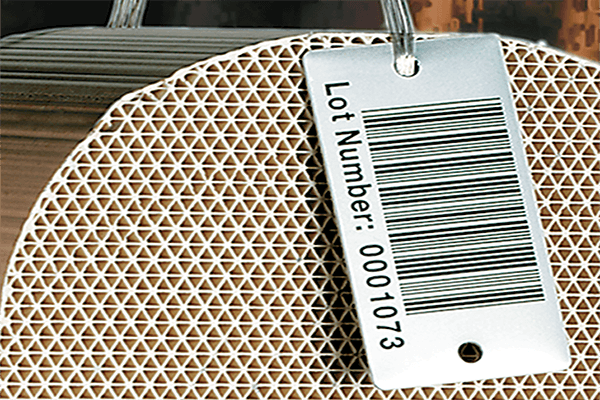

Metal Barcode Tags combine reliability with the durability you have come to expect with any Metalcraft product.

Tabbed Metal Barcode Nameplates have a convenient break-away tab to assist with liner removal.

Our Barcode Hang tags are removable, reusable solutions for a variety of applications.

Metalcraft’s Removable Paint-Mask Barcode Labels have a unique one-time removable paint-mask.

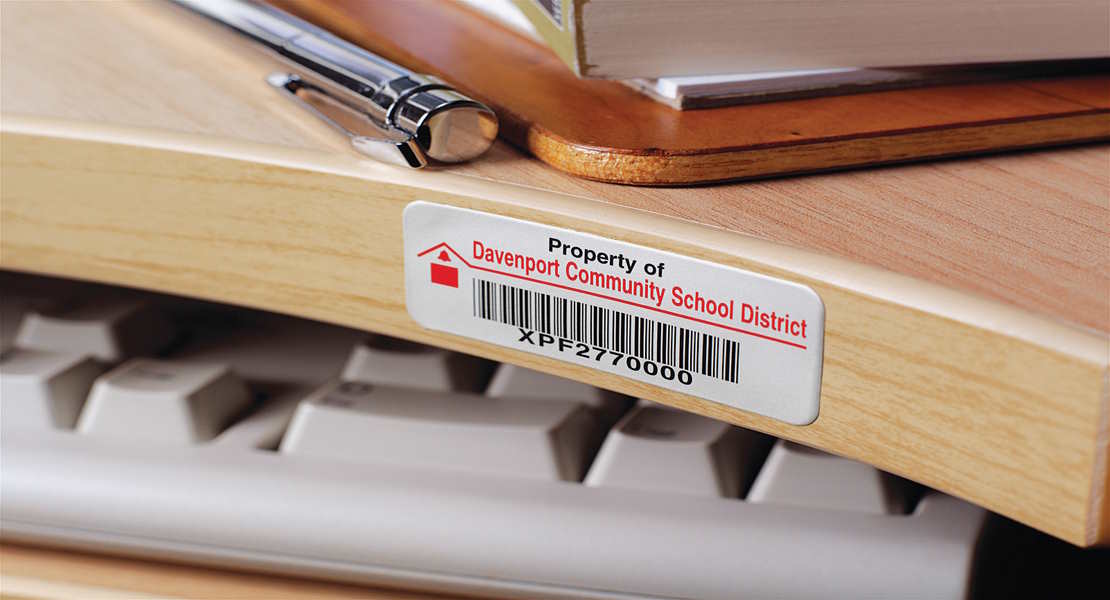

Metalcraft’s Premium Polyester Barcode Labels provide both flexibility and functionality for your asset tracking needs.

Metalcraft’s High Temperature Metal Barcode Nameplates are ideal for temperatures from 900°F - 1200°F.

Metalcraft’s Paint-Resist Metal Barcode Nameplates can withstand many paint applications while sporting a color design.

Our flexible Foil Barcode Labels conform to surfaces while withstanding chemicals, abrasion, solvents and high temperatures.

Regular barcode labels will not stand up to repeat paint applications, but Metalcraft’s Permanent Paint-Mask Barcode labels will.

Metalcraft's Thermalmark Polyester Labels offer the durability of a pre-printed label with the flexibility to custom print information on-site as needed.

Metalcraft’s Premium StyleMark Labels use a flexible polycarbonate material with a textured, non-reflective finish.

Our CRAFTMARK Polyester Barcode Labels are printed using our thickest polyester and a .0035” thick adhesive.

Gain the advantage for your asset tracking solution with Metalcraft’s ID Advantage Barcode Labels.

What is work in process?

Work in process (WIP) refers to goods or products that are in the process of being manufactured or transformed in a production system. It represents the intermediate state between raw material and finished goods. Work in process includes items that have undergone some degree of processing but are not yet completed.

Understanding the work in process is crucial for production planning, resource allocation, and managing the overall efficiency of the manufacturing process. It is also important for financial reporting, as the value of work in process contributes to the calculation of the cost of goods sold and the overall valuation of inventory on a company’s balance sheet. Efficient management of work in process contributes to reduced lead times, improved production efficiency, and better overall supply chain performance.

Why do companies track work in process?

Companies track work in process (WIP) for several important reasons, each contributing to efficient production, financial management, and overall business performance. Here are key reasons why companies track work in process:

- Production Planning and Scheduling - tracking WIP helps in planning and scheduling production activities which allows companies to optimize production schedules, allocate resources effectively, and ensure timely completion of products.

- Resource Allocation – understanding WIP levels assists in allocating resources such as labor, machinery, and materials which improves productivity and reduces the risk of bottlenecks in the production process

- Quality Control – monitoring WIP allows companies to implement and maintain quality control measures during production which ensures that products meet quality standards before advancing to the finished goods stage, reducing defects and rework.

- Cost Management – WIP is part of the overall inventory, and tracking it is essential for accurate cost accounting which helps determine the cost of goods sold (COGS), assess production costs, and calculate the value of inventory on financial statements.

- Lead Time Reduction – monitoring WIP aids in identifying and addressing bottlenecks or delays in the production process which reduces lead times, improves responsiveness to consumer demands, and enhances overall operational efficiency

- Supply Chain Visibility – companies track WIP to enhance visibility into the supply chain which facilitates coordination with suppliers, helps manage dependencies, and allows for proactive problem-solving in the production chain.

- Regulatory Compliance – some industries and regulatory environments require companies to maintain accurate records of WIP which helps comply with industry regulations, quality standards, and financial reporting requirements

- Continuous Improvement – WIPD tracking provides data for performance analysis and continuous improvement initiatives which enables companies to identify areas for efficiency gains, process optimization, and overall improvement in production processes

- Inventory Management – WIP is a component of overall inventory, and tracking it is crucial for effective inventory management which prevents overproduction, stock outs, and ensures a balanced and well-managed inventory level

Tracking work in process is integral to optimizing production processes, maintaining financial accuracy, and enhancing overall business performance. It supports the principles of lean manufacturing, helps companies respond effectively to market demands, and contributes to long-term sustainability and competitiveness.

Ultimate Guide to Metal Tags

This sourcebook will go into detail on the key benefits of metal tags, as well as how to ensure you get the right one for your application.

Download NowFrom The Asset Tracking Blog

In High Demand: The Growing Popularity of Photo Anodized Metal Tags in Asset Management

Learn why Metalcraft's Photo Anodized metal asset tags and foil products are in such high demand and find out more about our PHA 5 Point Promise.

How Custom Metal Tags Can Improve Equipment Management

Custom metal tags can improve equipment management by providing a reliable and customizable way to identify, track and maintain equipment.

Metalcraft announces Signature™ Printed Nameplates

Metalcraft retires screen-printed “AUTOGRAPHS” product line in favor of a digitally printed product, Signature™ Printed Nameplates.

Work-in-Process Case Studies

Strong As Steel

McNeilus, Metalcraft team up to provide supply chain and IUID tags for customer

Winning Combination

Hawk Technology and Metalcraft team up to provide automated RFID work-in-process solution

Opportunity

A manufacturer of a high-volume metal components wanted to track a part from the raw material stage through manufacturing and installation into the final product. In addition, they wanted to automate the collection of real-time production data and provide a more secure way of validating warranty claims once the products are in the field.

Barcoding Barrels helps wineries capture, keep information

Raymond Vineyards' barrel tracking reinforces winemaking tradition