For modern manufacturing processes, product traceability and accuracy are critical. And companies are facing increased pressure to streamline their manufacturing processes to ensure accurate and on-time product deliveries. This means implementing solutions that give immediate data insights as most manufacturing facilities transition to Industry 4.0. Metalcraft has partnered with many manufacturers for everything from asset tracking and tracing to managing work in process conveyor belt efficiency, and we have our hands in the future as this industry adapts and transitions to 4.0.

An example of our next-gen technology is that with RFID-enabled asset management, you can auto-fill tracking information quickly on asset arrival without the need for any human intervention. This can theoretically happen at as many locations as you need per the application. By auto-filling information and delivery statuses, RFID eliminates both the labor requirements and human error possibilities of other forms of tracking while increasing production visibility and inventory accuracy.

No matter what, you want to know you have Metalcraft engineers by your side as we provide cost-effective ID technologies that:

- Keep track of inventory automatically

- Receive and assign goods, knowing where everything is

- Reduce unnecessary equipment purchases and incorrect deliveries

- Discourage theft and counterfeiting

- Provide real-time data on where every tracked device is

- Create supply-chain process optimization and transparency

- Provide a real-time account of safe handling

As we help manufacturers automate their processes, we’re partnering to best understand their unique applications and how we can help optimize their supply chain with solutions that give real-time results. And if there isn’t an “off the shelf” solution, we are known for our customization, being the first company to offer customizable RFID inlays, as one example. Now that’s ID Made Better®.

These .016” thick aluminum nameplates offer the greatest flexibility in nameplate design.

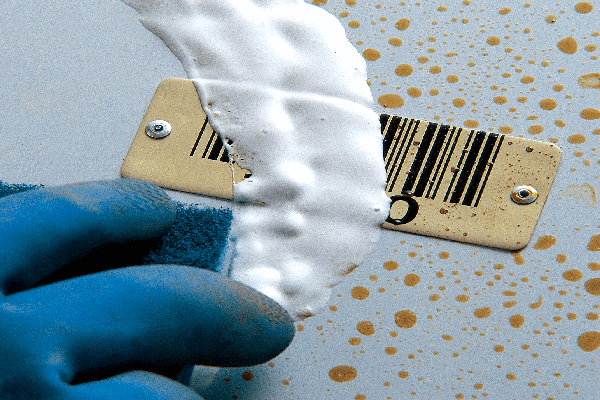

Teflon® Coated Nameplates are easy to clean, acid-resistant and temperature-resistant up to 500 °F.

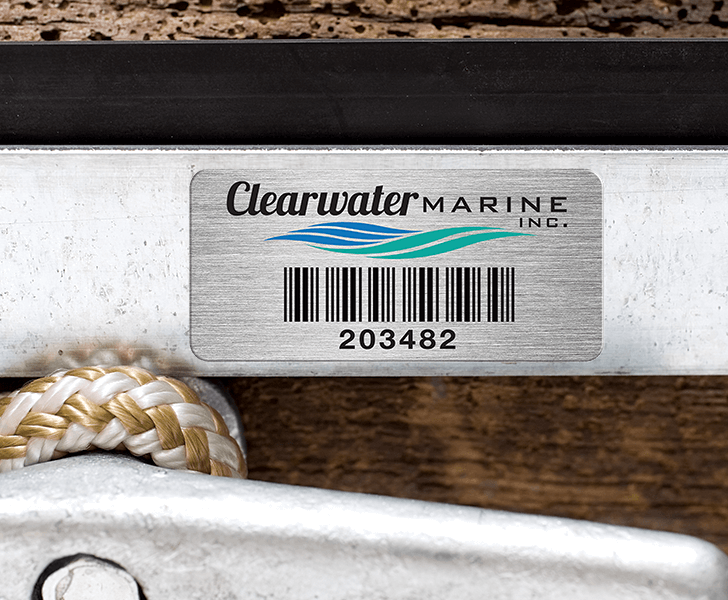

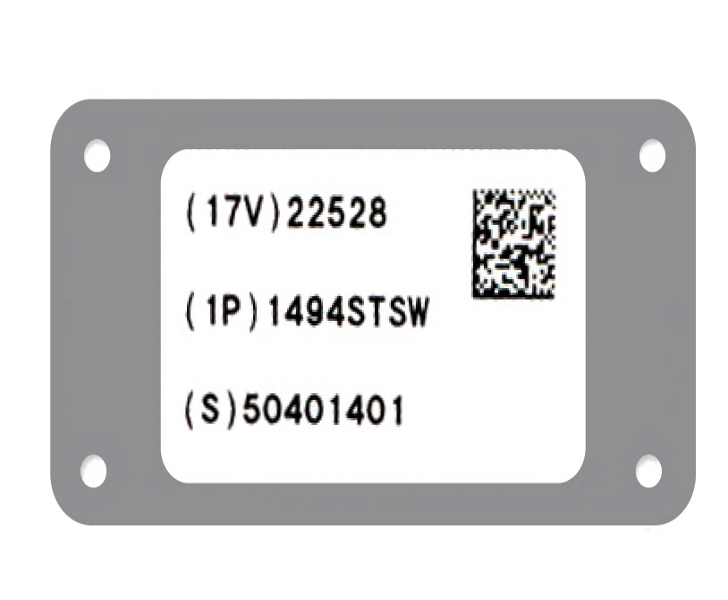

Metal Barcode Tags combine reliability with the durability you have come to expect with any Metalcraft product.

Tabbed Metal Barcode Nameplates have a convenient break-away tab to assist with liner removal.

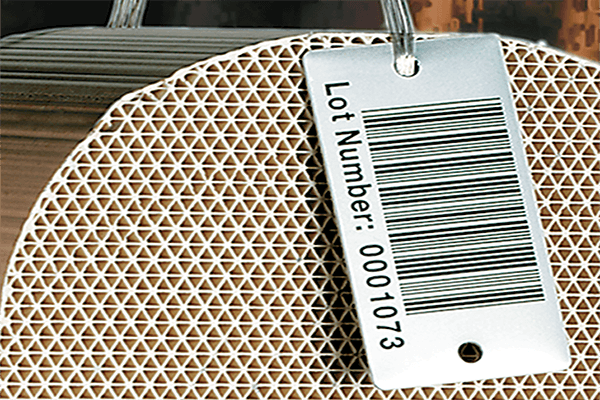

Our Barcode Hang tags are removable, reusable solutions for a variety of applications.

Metalcraft’s Removable Paint-Mask Barcode Labels have a unique one-time removable paint-mask.

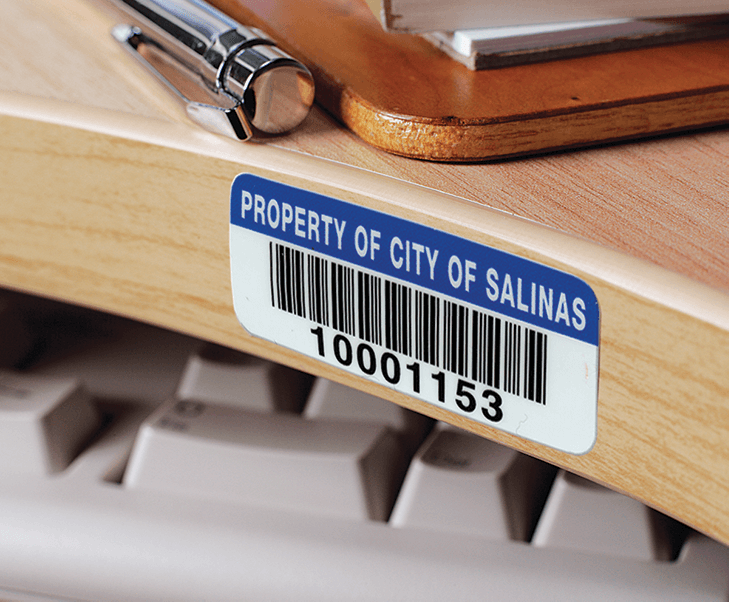

An ideal solution for indoor asset tracking, “VALUMARK” Labels are an effective and affordable identification solution.

Metalized Silver Polyester Labels have the appearance of metal without the accompanying price tag.

Metalcraft’s Premium Polyester Barcode Labels provide both flexibility and functionality for your asset tracking needs.

Metalcraft’s High Temperature Metal Barcode Nameplates are ideal for temperatures from 900°F - 1200°F.

Embossed Nameplates combine durability with one of the most impressive design features we offer, making your company logo stand out – literally! Add your logo, trademarks, stylized or block type, as well as one or two colors with standard or custom options.

Metalcraft’s Paint-Resist Metal Barcode Nameplates can withstand many paint applications while sporting a color design.

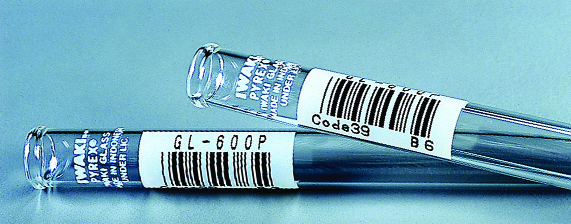

Our flexible Foil Barcode Labels conform to surfaces while withstanding chemicals, abrasion, solvents and high temperatures.

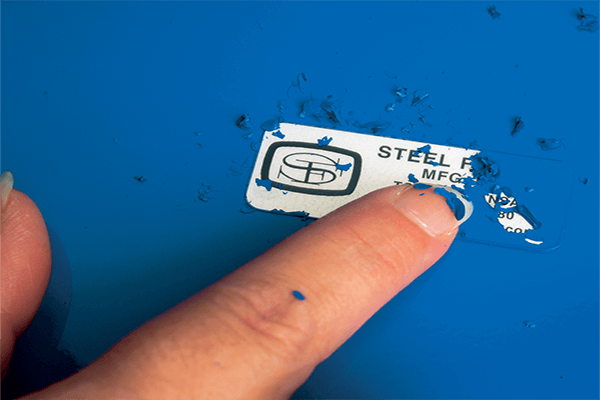

Regular barcode labels will not stand up to repeat paint applications, but Metalcraft’s Permanent Paint-Mask Barcode labels will.

Metalcraft's Thermalmark Polyester Labels offer the durability of a pre-printed label with the flexibility to custom print information on-site as needed.

Metalcraft’s Premium StyleMark Labels use a flexible polycarbonate material with a textured, non-reflective finish.

Our CRAFTMARK Polyester Barcode Labels are printed using our thickest polyester and a .0035” thick adhesive.

Gain the advantage for your asset tracking solution with Metalcraft’s ID Advantage Barcode Labels.

Printed using ceramic ink on a thin ceramic layer that is fired and fused to a heat-resistant stainless steel substrate. Withstands moderate to harsh chemical conditions and extremely high temperatures.

An unfired ceramic label is fused onto the product during the heat treatment process of the production line.

Ultimate Guide to Metal Tags

This sourcebook will go into detail on the key benefits of metal tags, as well as how to ensure you get the right one for your application.

Download NowFrom The Asset Tracking Blog

Metalcraft announces Signature™ Printed Nameplates

Metalcraft retires screen-printed “AUTOGRAPHS” product line in favor of a digitally printed product, Signature™ Printed Nameplates.

Metalcraft Implements Digital Printing Technology

Metalcraft introduces their new Signature™ Printed Nameplate or metal nameplate product line using inkjet technology.

What is the Best Solution for Asset Tracking in Manufacturing?

What is the best solution for asset tracking in manufacturing? Read our latest article to learn how to determine what identification products in your asset tracking solution in manufacturing.

Manufacturing Case Studies

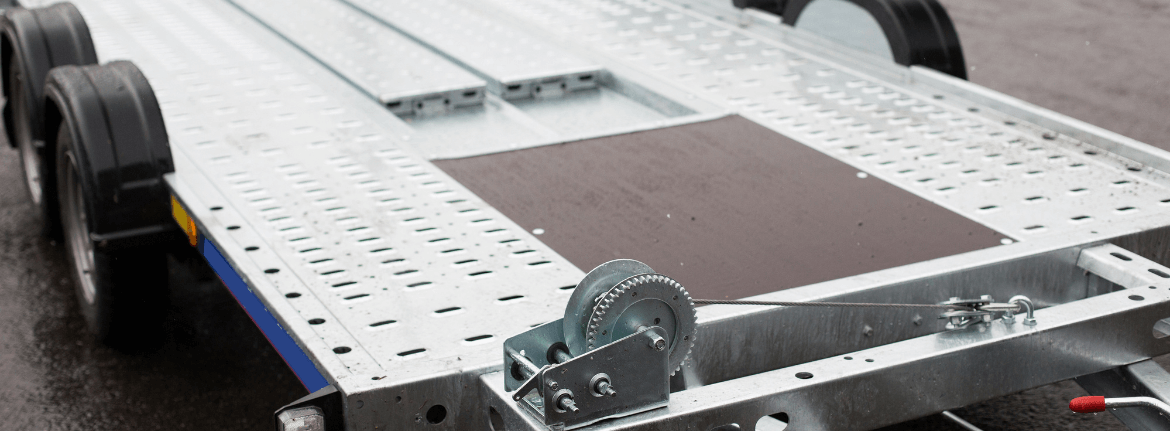

Durable Tags Never "Trail" the Competition

Signature Nameplates lead to strong product identification solution for trailer manufacturers

Building Brilliance

Background

For more than 55 years, cHc Manufacturing has been the single source for custom fabrication and installation of structural steel, industrial catwalks, miscellaneous metals, steel stairs and ornamental iron.

"Building" a Reputation for Quality

Metalcraft partners with Old Hickory Buildings to provide attractive product identification solutions.