RFID technology has become an essential asset in the aviation and aerospace industries, revolutionizing operational processes and bolstering overall efficiency. In the dynamic evolution of these sectors, RFID stands as a crucial tool, providing tailor-made solutions to meet specific requirements and actively contributing to the continual progress of aviation and aerospace operations.

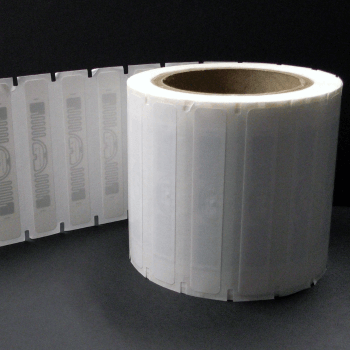

Reduce time and labor from hours to just minutes with increased accuracy while improving daily presence checks and expiration date inspections with our RFID Life Vest Labels.

What is the use of RFID in Aviation?

Radio frequency identification (RFID) technology plays a crucial role in various applications within the aviation industry. Some of the key uses of RFID in aviation include:

- Baggage Tracking – RFID tags are often attached to luggage to enable efficient tracking throughout the entire journey. This helps airlines and airports reduce the chances of lost or misplaced baggage.

- Asset Management – RFID is employed for tracking and managing various assets within the aviation industry, such as tools, equipment, and maintenance components. This improves inventory control, reduces the likelihood of errors, and enhances overall operational efficiency.

- Maintenance and Inventory Management – RFID technology is used to monitor and manage the maintenance schedules of aircraft components. It helps in keeping track of when parts were last inspected, repaired, or replaced, facilitating timely maintenance and reducing the risk of equipment failure.

- Access Control and Security – RFID cards or badges are used for access control to restricted areas within airports or aircraft. This enhances security by allowing only authorized personnel to enter specific zones.

- Inventory and Supply Chain Management – airlines use RFID to manage their inventory and streamline the supply chain. This includes tracking the movement of goods, spare parts, and other materials from manufacturers to airports and between different facilities.

- Flight Operations – RFID technology is employed in the tracking of flight crew uniforms and equipment. This ensures that the right personnel have access to the right gear, contributing to operational safety and efficiency.

- Aircraft Parts Authentication – RFID tags can be used to verify the authenticity of aircraft parts. This is important for safety and compliance, as it helps ensure that only genuine and approved components are used in aircraft maintenance and repair.

Using RFID Technology to Track Life Vests

RFID tags play a pivotal role in enhancing safety measures aboard airplanes, particularly in the tracking of life vests.  These small, lightweight tags are affixed to each life vest, enabling airlines to efficiently monitor the status and location of these crucial safety devices. Through RFID technology, airline personnel can easily conduct regular checks and real-time audits, ensuring that every life vest is in its designated place and in proper working condition. This streamlined tracking system not only expedites routine inspections but also contributes to swift responses in emergency situations, as it allows for quick identification and replacement of any malfunctioning or missing life vests. Overall, the integration of RFID tags for life vest tracking exemplifies a proactive approach towards aviation safety, fostering a more secure and well-maintained air travel environment.

These small, lightweight tags are affixed to each life vest, enabling airlines to efficiently monitor the status and location of these crucial safety devices. Through RFID technology, airline personnel can easily conduct regular checks and real-time audits, ensuring that every life vest is in its designated place and in proper working condition. This streamlined tracking system not only expedites routine inspections but also contributes to swift responses in emergency situations, as it allows for quick identification and replacement of any malfunctioning or missing life vests. Overall, the integration of RFID tags for life vest tracking exemplifies a proactive approach towards aviation safety, fostering a more secure and well-maintained air travel environment.

RFID in Aerospace Advantages

RFID (radio frequency identification) technology in the aerospace industry provides various benefits, contributing to improved efficiency, safety, and overall operational excellence. Here are some key advantages.

- Asset Tracking and Management – RFID enables accurate and real-time tracking of aerospace assets, including tools, equipment, and components. This ensures efficient inventory management and helps prevent loss or misplacement of critical items, leaving to cost savings and streamlined operations.

- Maintenance and MRO (Maintenance, Repair, and Overhaul) Efficiency – RFID tags on aircraft components facilitate maintenance tracking, allowing for timely inspections, repairs, and replacements. This helps enhance the overall safety and reliability of aircraft, reduce downtime and optimize maintenance processes.

- Supply Chain Visibility – RFID technology improves visibility and traceability in the aerospace supply chain. It allows for real-time monitoring of the movement of parts and materials, aiding in better logistics planning, inventory management, and reducing the risk of delays.

- Reduction of Human Errors – automation through RFID technology reduces the chances of human errors in tasks such as inventory management, maintenance tracking, and tool control. This leads to increased accuracy and reliability in aerospace operations.

- Data Accuracy and Real-time Monitoring – RFID systems provide accurate and real-time data, allowing for better decision-making. This is particularly important in the aerospace industry, where precise information is critical for safety, compliance, and operational efficiency.

- Cost Savings through Process Optimization – RFID contributes to cost savings by optimizing processes, reducing manual labor, minimizing errors, and improving overall workflow efficiency in aerospace operations.

RFID Tracking Aerospace Parts and Components

RFID technology has revolutionized the aerospace industry by providing a sophisticated solution for tracking and managing parts and components throughout their lifecycle. The use of RFID enabled tags on aerospace parts ensures a seamless and efficient tracking system, allowing real-time visibility into the location, status, and history of each component. From manufacturing through maintenance and eventual retirement, RFID technology enhances the accuracy of data collection, reducing manual errors and streamlining operations. This trackability facilitates timely maintenance interventions, improves inventory management, and enhances overall safety and compliance, With RFID, aerospace manufacturers and operators can optimize their supply chain, reduce downtime, and ensure that critical components are always in the right place at the right time, contributing to increased operational efficiency and the overall reliability of aerospace systems.

Customizable RFID Solutions for Aerospace

Customizable RFID solutions have emerged as a powerful tool in the aerospace industry, offering tailored applications to meet specific operational needs. These solutions are designed to address the unique challenges of the aerospace sector, providing flexibility and adaptability. Whether it’s for tracing components in manufacturing, streamlining maintenance processes, or enhancing overall asset management, customizable RFID solutions offer a versatile platform. The technology allows aerospace organizations to configure RFID systems according to their specific requirements, ensuring seamless integration with existing processes. This flexibility not only optimizes workflow efficiency but also enables precise data collection for tasks such as inventory management and compliance tracking. The ability to customize RFID solutions empowers aerospace entities to implement targeted, scalable, and future-proof systems that cater to their evolving needs, ultimately contributing to improved operational performance and cost-effectiveness.