Asset management is vital to the warehousing and distribution industry, likely more than any other industry here. That’s because keeping track of inventory and sending products to the right locations (asset tracking)is the core of what this industry is all about. In addition to being able to better manage one-off inventories of consumer goods, what’s more important is the reusable nature of asset management technologies for pallets and barrels. These items may be used for multiple years to ship products back and forth.

Whether your asset is sitting in a storage facility or actively in transit, it has to be properly tagged so that you can keep track of it. Large shipping containers, pallets and individual packages can all use asset tags so that your inventory management is not compromised by harsh handling conditions.

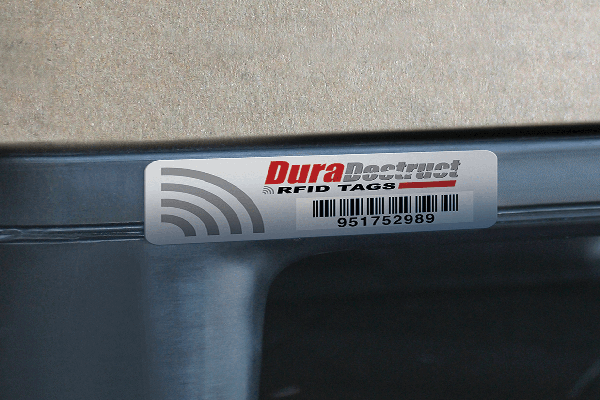

Durable and reusable RFID tags offer great benefits here, as well. RFID tags are often built to withstand years of use, even in hot and dirty delivery environments. Automating the QA process on load verification also helps to minimize missed deliveries to stores, which is a problem that costs distribution companies $25-30 million per year nationwide.

Metalcraft engineers know this industry inside and out, and can provide you with durable, reliable, cost-effective ID technologies that:

- Keep track of inventory automatically

- Receive and assign goods, knowing where everything is

- Prevent shortages

- Reduce unnecessary equipment purchases and incorrect deliveries

- Discourage theft and counterfeiting

- Provide real-time data on where every tracked item is

- Create supply-chain process optimization and transparency

- Provide a real-time account of safe handling

In warehouses and distribution centers, everything is subjected to harsh conditions. Call in the “tough” experts” to provide you with solutions that give real-time results, saving you time and money--now that’s ID Made Better®.

Metalcraft’s RFID Flex Hard Tags are specifically designed for assets that need a rugged, yet flexible, polymer RFID tag that is more cost effective than traditional hard tags and has a reliable, consistent read range performance.

Perfect for tracking returnable containers such as pallets, crates or totes, Metalcraft’s Standard RFID Tag attaches directly to non-metal assets.

Perfect for applications that need a bit more than just adhesive, Metalcraft’s Stick and Staple RFID Tag attaches directly to assets with adhesive with the added option of stapling the tag, ensuring the tag stays attached to those hard-to-adhere surfaces while not damaging the inlay.

An RFID tag that truly lives up to its name. The Universal RFID Hard Tag features surface-independent tags with a patented inlay design used to obtain excellent read ranges regardless of the surface – metal, plastic, even wood.

The only thing “mini” about this tag is its size! With a smaller footprint and lower profile, the Onsite Printable Universal Mini RFID Tag easily fits where other tags may be too large and obtrusive and still gives incredible read ranges compared to other tags in its class.

The Universal Micro RFID Tag measuring 1 7/8” x 5/8” is a great solution to your identification projects that require the smallest RFID tag with great read range.

If you are looking for a small RFID tag, the Universal Mini RFID Tag is the one for you! The Universal Mini RFID Tag may be small in size, but it packs a powerful punch! Its compact design and slim profile make it ideal for spaces where larger tags would be cumbersome.

The closest thing you will find to a "one-size-fits-all” RFID solution!

From The Asset Tracking Blog

What Makes for a Good Pallet Label?

Using a durable pallet label in your company's supply chain provides multiple benefits including improved accuracy and efficiency and more!

Metalcraft's RFID Tag Tops In Industry Reports Study

University of Texas at Arlington study confirms that an RFID tag from Metalcraft will perform reliably and accurately with better than average readability.

What is RFID? A Basic Guide to Radio Frequency Identification

Integrated chip ... antenna ... substrate .... these are all parts of what makes up and RFID tag. Our guide explains these components as well as takes a look at the different types of RFID tags.

Warehouse - RFID Case Studies

Protecting Pallets

When customers wanted to make their systems smarter by incorporating RFID technology, TriEnda teamed up with Metalcraft to offer RFID as a standard product, making it easier to track returnable containers.