SRCA finds Metalcraft expertise to mark aircraft

Challenge: Label Selection for Legacy UID Compliance

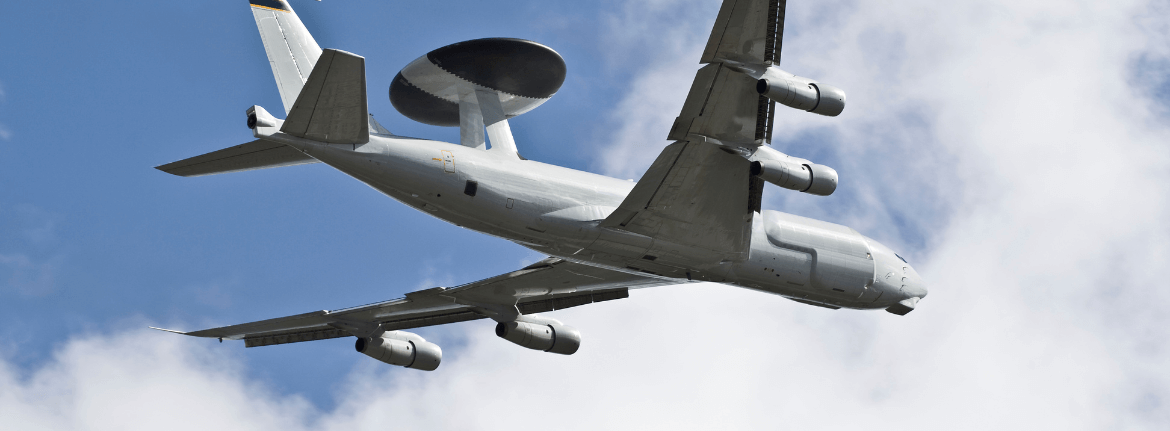

The Department of Defense (DoD) has mandated that certain assets and property it owns, including assets in the possession of Defense contractors, be tracked with unique, machine-readable identification numbers (UID). The UID policy aims to modernize the largest supply chain in the world – enabling government and private contractors to manage inventory more effectively. Since the policy began to take shape in 2003, Defense contractors have worked to develop systems for complying with the two main processes required by the mandate – marking and registry of individual items. Marking requires a machine-readable, permanent identifier – a two-dimensional data matrix that is engineered to last the lifetime of the item. Each matrix enables unique identification of individual items using existing data elements, including the manufacturer's identification and the item's serial number, among other elements. The UID policy includes legacy items -- the millions of existing assets out there today. Legacy items are particularly challenging as they must be identified, marked and registered while spread around the world and shared by many organizations in and outside of DoD. Safety Research Corporation of America (SRCA) is a veteran-owned provider of software and services for commercial and DoD customers, including numerous contracts with the U.S. Army. In 2008, the Daleville, Alabama-based company won a contract for the Army's Airborne Reconnaissance Low (ARL) fleet IUID work – identifying, marking and registering the surveillance equipment on aircraft used for reconnaissance around the world. While SRCA was the contractor and brought considerable experience with Army assets, they were not experts in labels, UID marking and scanning. Dana Greiner, Project Manager at SRCA, asked for assistance.

Solution: Metalcraft UID expertise, labels and services

Greiner was introduced to Metalcraft in 2008, as SRCA was studying requirements for marking the legacy Army surveillance equipment aboard De Havilland Canada DHC-7 aircraft. "They took time to explain things for us," said Greiner. "It was nice to have someone with the same level of knowledge about an unusual program. Metalcraft was able to lead us down some good paths." When Greiner met Metalcraft again at the UID Forum in April 2009, she was ready to make decisions on label products, and Metalcraft announced the ability to handle registration and submission to DoD's UID Registry. "At that point, Metalcraft allowed one-stop shopping," said Greiner. "We just needed it done. Metalcraft had demonstrated flexibility and understanding of UID." UID nameplate and label specialists at Metalcraft produced designs for Greiner on anodized aluminum – one of the six families of label products they customize for Defense contractors. The nameplates included the required UID data matrix and optional linear bar codes, remaining machine and human readable at close range. Moreover, Metalcraft verified the print quality of the UID, validated the information contained in each UID label to ensure speedy acceptance by DoD and planned to manage the important registration marked legacy items.

Results: UID compliance and more

SRCA completed their first marking of ARL aircraft at Sierra Nevada Corporation's (SNC) Hagerstown, MD location in June 2009. "Physically, marking is fast," says Greiner. "It's everything else that takes time and knowledge." Greiner's team is photographing the applied UID labels to ensure continuity for future aircraft marking, as well as securing the capture of legacy asset information for Metalcraft's submission to the UID Registry. As SRCA continues to mark ARL aircraft, they are developing a logistics management website in partnership with SNC and Telford Aviation that will enable validated logisticians to track data beyond UID – identification information, warranty notification, and item location. Meanwhile, Greiner continues to travel the world marking aircraft and expects to have the bulk of the Primary Mission Equipment marked and registered by the end of the year with Metalcraft's help. "Dealing with Metalcraft has been very productive," said Greiner. "We've found them to be a wonderful company."

To learn more about our asset tracking solutions, contact us today at [email protected].