As the RFID market has matured, more end-use segments - from retail to pharma - can benefit from product traceability.

For label and package printers, RFID is no longer just a concept. In fact, RFID has matured to a point where nearly every vertical can benefit from the technology. The benefits range from fighting counterfeit goods with traceability to providing inventory management for retail stores.

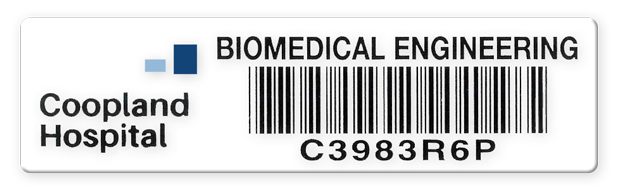

Metalcraft, a 72-year-old manufacturer of identification products, has seen this market grow from its infancy. The company got its start labeling staplers with metal nameplates. Those capabilities evolved throughout the years to the point where in 2004, Metalcraft made a large equipment purchase to gain entrance into the RFID market. Seeing the vast potential for RFID labeling, Metalcraft continued to invest R&D resources into the space.

"We began dabbling in RFID once we started to understand the polymers and adhesives," explains Kyle Bermel, president of Metalcraft. "We were one of the first in this market, and what really put Metalcraft on the map for RFID was our on-metal tags. In 2006 we worked with Iowa State University to fund a patent that created a tag that worked really well on metal and various other surfaces. The goal was to get to a place where you didn't need multiple tags for different surfaces you were trying to label. That technology is still part of our go-to-market strategy today."

While there have been drawbacks to using RFID in the past - namely, cost and technology limitations - it has reached a point where brands can now reliably benefit.

"Initially with RFID, you were always trying to figure out what worked and what didn't," states Bermel. "I think the key is the RFID industry is no longer at a point of proving the technology works - the industry knows it works. Now we're at a point of figuring out how the RFID technology can be used in different systems and across different verticals. Retail has done a nice job of proving it works through numerous use cases. With what retail has created, other industries are looking at how they can use it to improve their businesses."

Retail has been the key driver for RFID technology. The sensors placed in retail labels and tags are critical for tracking products throughout the supply chain. For example, a customer can look online and see that a clothing store has a specific sweater in a specific size. That product is traceable with the use of RFID.

RFID also promotes consumer engagement. "The biggest thing with retail is omni-channel capabilities," comments Bermel. "You go on Target.com to find a white t-shirt and then you go to the store because it says online that it's there. If it's not there, you're not going to shop at Target again. But RFID enables the retailer to be sure that the t-shirt is there. And that's a big reason why adoption in retail is so high."

Pharmaceutical and healthcare are also viable avenues for RFID technology. Plus, the retail space will continue to grow, as well, especially as companies look at ways to tag more items on the shelf.

"The RFID market will continue to keep growing within multiple verticals because it's been proven," explains Bermel. "The pharmaceutical space just needs to figure out the data structure and who owns it. For pharma right now, it's just about making sure it's open source and that the standards are in place to make sure everyone can utilize it. That will be very beneficial for pharmaceuticals moving forward."

"Tolling is one of the big markets for RFID too, along with vehicle tracking," he adds. "Car washes are also seeing strong demand, where people buy a month subscription. Those are not typically an off-the-shelf inlay that goes into those parts."

In the past two years, Metalcraft has also brought production of the actual inlay into the US. The company has purchased equipment, where it can assemble the actual inlay. "We can produce the label already, but we added the ability to make the subcomponent, the inlay," remarks Bermel. "We also provide that capability to our partners."

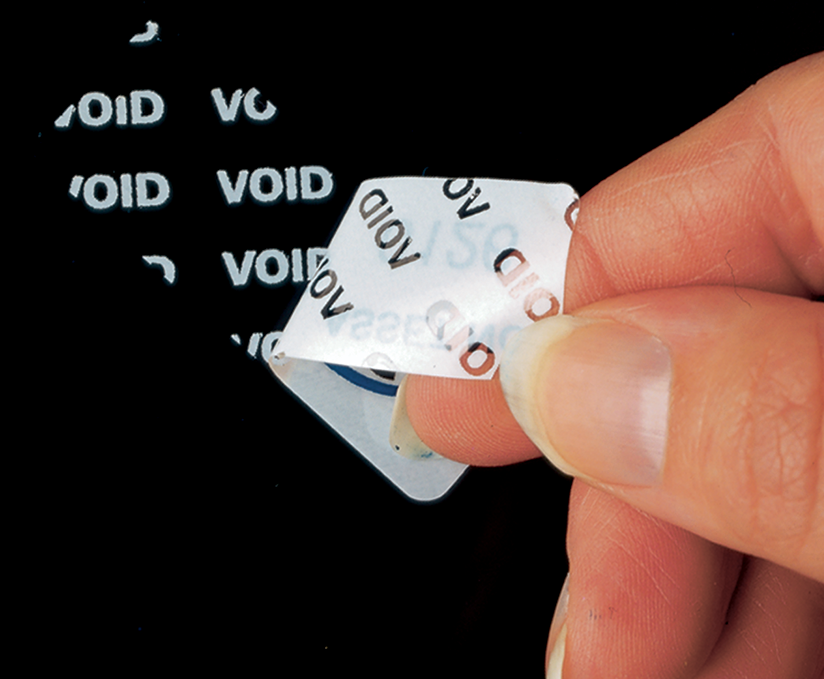

Metalcraft's products can often be used for tracking. This will include durable items that require shipping such as returnable containers, computers, IT equipment and more. The company also specializes in tamper-evident and destructible RFID products.

"We offer destructible type products that shouldn't function after they've been destroyed or removed," says Bermel. "The car wash is an example, where you use the membership for a month. You shouldn't be able to remove the tag and put it on your wife's car and let her use it. If you do try to remove the tag, yours doesn't work anymore."

As the manufacturing industry hones in on automated capabilities, the future forecast for RFID is bright, adds Bermel. "As we become more focused on automation RFID will just continue to grow within that because of its ability to work autonomously once the tag is applied," he says.

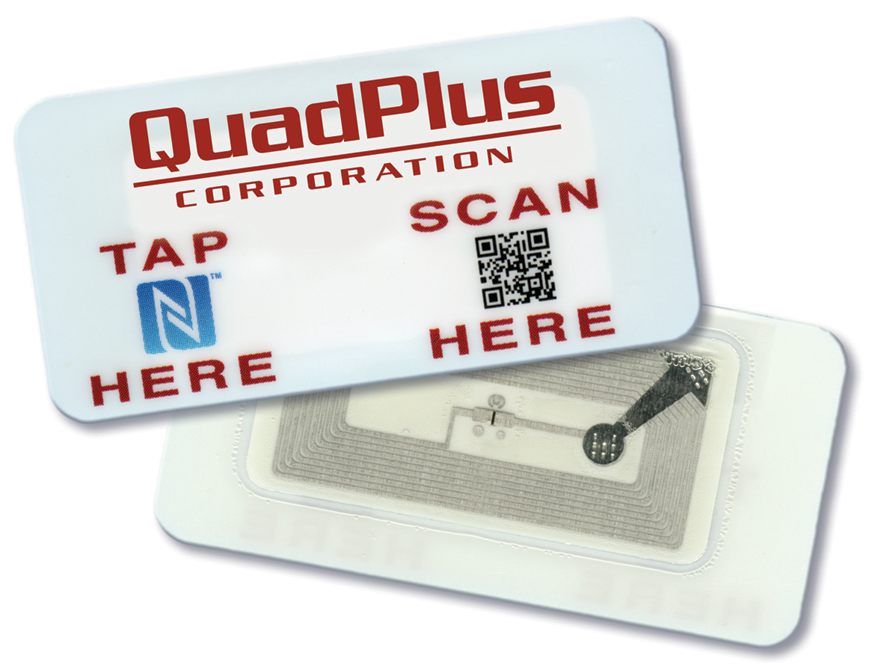

Understanding NFC

NFC also has a strong space in the RFID field. For example, the chips in credit cards that utilize contactless payment feature NFC capabilities.

"NFC is a form of RFID," states Bermel. "UHF, HF, and LF communications are the different frequencies. UHF is what you typically think of from a retail standpoint when you're talking about a tagged shirt at Target. NFC is near field communication so that's built on the 13.56-megahertz band, which is high frequency, as opposed to UH frequency. And the difference there is the proximity at which the tag can be read. NFC pinpoints one tag at a close proximity, and that's why it's used a lot in security such as access badges."

NFC is advantageous because the reading capabilities are available in modern smartphones. "The hardware is already available to every person, where one of the bigger investment costs for UHF RFID is that hardware infrastructure," adds Bermel. "I've always been a big proponent of NFC. It's taken longer to be adopted than it should, but there a lot of successful use cases out there."

To learn more about RFID tags, please contact us at [email protected].