In inventory management applications, where accurate and efficient inventory management is crucial, RFID chip tracking offers substantial benefits.

How RFID Chip Tracking Helps Inventory Management

RFID (radio frequency identification) chip tracking is a technology that uses radio waves to identify and track objects equipped with RFID tags or chips. RFID has proven to be highly effective in improving inventory management across various industries. Here's how RFID chip tracking helps with inventory management.

- Automation and Speed - RFID technology enables automatic and rapid data capture. As tagged items move within the range of RFID readers, the information is read without requiring a direct line of sight or manual scanning. This significantly speeds up the process of inventory tracking compared to traditional barcode scanning.

- Accuracy - Human errors can occur during manual data entry or barcode scanning, leading to inaccuracies in inventory records. RFID reduces the likelihood of errors because the information is read electronically and directly from the RFID tag. This results in more accurate and reliable inventory data.

- Efficiency - Traditional inventory management methods can be time-consuming and labor intensive. RFID streamlines the process, enabling staff to quickly conduct inventory checks and locate specific items without extensive manual effort.

- Bulk Scanning - RFID can read multiple tags simultaneously, even if they are in close proximity. This is particularly useful for data centers with racks of equipment or storage areas where numerous assets are stored together. Bulk scanning accelerates the process of tracking multiple items at once.

- Improved Visibility - RFID provides comprehensive visibility into the movement and utilization of assets. Data center managers can monitor when assets are moved, identify usage patterns and ensure that assets are being optimally utilized.

- Integration with Management Systems - RFID systems can be integrated with existing inventory management software and databases. This allows for seamless data exchange and integration with other data center management tools.

- Auditing and Compliance - RFID tracking provides an accurate and auditable record of asset movements and inventory changes. This is valuable for compliance purposes and it helps data centers to maintain accurate records for audits.

Can RFID Chips Be Tracked?

Yes, RFID chips can be tracked using RFID technology. RFID is a technology that uses radio waves to communicate between an RFID tag that contains the chip and an RFID reader. The reader emits radio waves that power the tag and read the information stored on it. This information includes a unique identifier or other data associated with the tagged item.

Here's how the tracking process generally works:

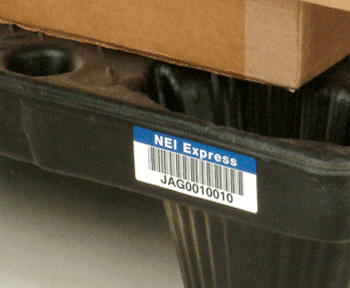

- Tagging - Each item that needs to be tracked is equipped with an RFID tag, which contains a small microchip and an antenna. This tag can be passive (powered by the energy from the reader) or active (with its own power source).

- RFID Reader - RFID readers emit radio waves that activate the RFID tags in their range. These readers can be stationary or handheld, and they are strategically placed in areas where tracking is needed.

- Communication - When the RFID tag receives energy from the reader, it responds by transmitting the information stored on its microchip. This information could be a unique identifier or other data specific to the item.

- Data Capture - The RFID reader captures the transmitted data from the tag. This data can then be processed by software and integrated into inventory management or tracking systems.

RFID tracking is commonly used in various industries for inventory management, supply chain tracking, asset management, access control and more. However, the tracking range of RFID is limited to a certain distance, and it generally requires the presence of RFID readers within that range to effectively track and monitor tagged items.

Can RFID Chips Track Exact Locations?

RFID chips can provide location information, but their ability to track an exact location depends on several factors and limitations.

- Range - The tracking range of RFID technology is limited. Passive RFID tags, which are powered by the energy emitted by RFID readers, typically have a shorter range compared to active RFID tags, which have their own power source. The range can vary from a few inches to many feet, depending on the type of tag and reader being used.

- Precision - RFID technology is generally better suited for identifying the presence of an item within a specific area rather than providing pinpoint accuracy.

- Environmental Factors - Physical obstacles, electromagnetic interference and other environmental factors can affect the performance of RFID systems. These factors can introduce errors and make it challenging to achieve highly accurate location tracking.

- Reader Density - To achieve better location accuracy, you would need a higher density of RFID readers, which can increase cost and complexity.

- Infrastructure and Costs - Creating an infrastructure with a dense network of RFID readers capable of achieving high-precision tracking can be costly and resource intensive.

For applications that require very precise and real-time location tracking, technologies like Real-Time Location Systems (RTLS) or Global Positioning System (GPS) are often better suited.

For more information on how RFID chip tracking helps inventory management, please contact Metalcraft at 800-437-5283 or [email protected].

| About the Author: Aaron HobertAaron Hobert is our RFID Technical Specialist. Hobert joined Metalcraft in September of 1994 as a Litho Press Operator, became the Autograph Team Lead in 1998 and in April 2005 he became the RFID Sales Support Rep. He was named our RFID Technical Specialist in 2008. Aaron lives outside Charles City with his wife Diane. Mobile Phone: 641-330-2660 Email: [email protected] Office: 3360 9th St. SW, Mason City, IA 50401 Office Phone: 641-423-9460 |