A company specializing in automated gate systems innovates with Metalcraft through custom RFID inlay designs.

Innovation is an idea that has been transformed into practical reality. At its core Radio Frequency Identification is innovation; however, innovation is kicked up a notch when RFID is combined with an application so unique that it requires custom inlay development.

Solving Theft with Custom RFID Inlay Designs

We were recently brought a unique opportunity for a custom RFID tag and inlay by a company specializing in automated gate systems for the shipping industry. They recognized the inherent need for digital records of tampering on shipping containers. Many cargo shipments are handled by third parties or multiple teams, leaving valuable items in the hands and under the supervision of many different people. It also exposes the shipments to thieves who want to steal and resell goods, along with competitors wanting to steal technology and more.

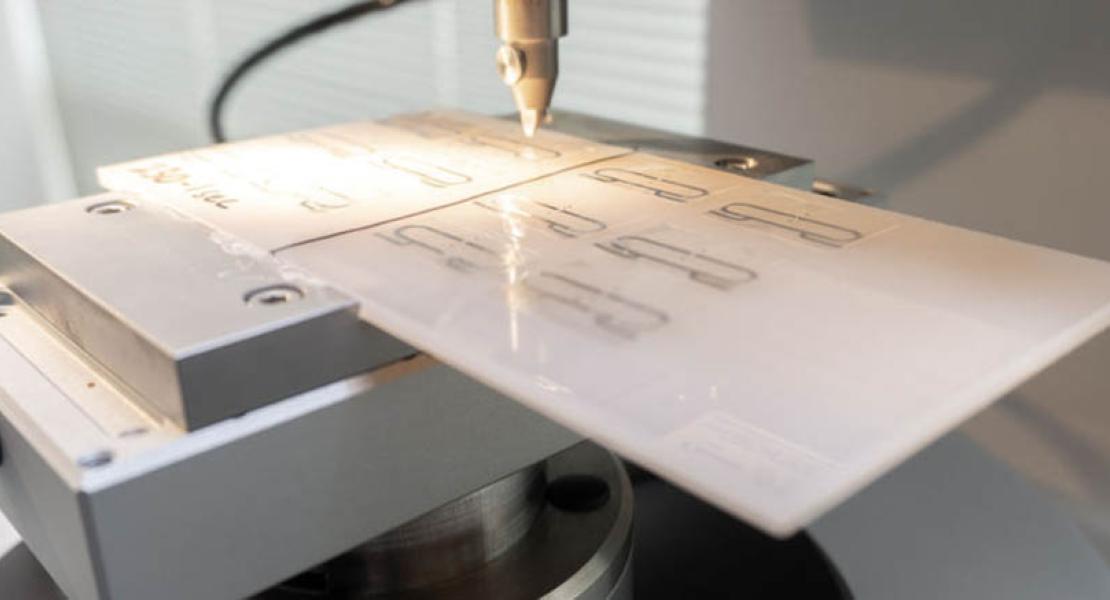

As part of their company’s ideation and innovation project, they hired an outside RF consultant to design an RFID inlay. They wanted the inlay molded into a finished good that would be used in the locks of shipping containers to detect if they have been opened as they pass through different ports. Once the gate systems company received the designs from the consultant, they shared those inlay designs with Metalcraft and, unfortunately, they proved ineffective in the application. However, Metalcraft RFID engineers reimagined the design, working with representatives from this company to design an RFID inlay that would actually work for their application.

Metalcraft RFID provided the gate systems company with a proof-of-concept pilot run of a few thousand pieces for which they purchased the tooling and material required to make the inlays.

This new part, jointly developed by Metalcraft’s RFID engineers and representatives from the company, worked perfectly, and the company deemed this a success. Although it didn’t move forward from POC, all sides embraced how beneficial it is to have an RFID partner skilled in custom RFID inlay design, development and manufacturing to make the process smooth for all parties involved.

To learn more about custom inlays, check out our white paper and contact us today at [email protected].

| About the Author: Marianne AlvaradoMarianne Alvarado is our Vice President of Sales. Alvarado joined Metalcraft in March of 2000 as a Territory Specialist, became Sales Manager in January 2022 and was named Vice President of Sales during August of 2023. She leads both the Outside and Inside Sales teams. Marianne lives in Davenport with her husband, Dave Beeman. Mobile Phone: 641-529-9492 Email: [email protected] Office: 3360 9th St. SW, Mason City, IA 50401 Office Phone: 641-423-9460 |